Modul - Permit System

-

Upload

caleb-conner -

Category

Documents

-

view

52 -

download

8

description

Transcript of Modul - Permit System

PERMIT SYSTEMSoehatman Ramli

Latar Belakang• Lingkungan industri khususnya yang

mengelola bahan berbahayasangatrawan terhadap bahaya kecelakaan.

• Pada umumnya kecelakaan terjadipada pekerjaan pemeliharaan.

• Perlu pengawasan dan pencegahanyang baik melalui sistem ijin kerja

• Lingkungan industri khususnya yangmengelola bahan berbahayasangatrawan terhadap bahaya kecelakaan.

• Pada umumnya kecelakaan terjadipada pekerjaan pemeliharaan.

• Perlu pengawasan dan pencegahanyang baik melalui sistem ijin kerja

Philosophy Ijin Kerja

Tujuan sistem Ijin Kerja

• mencegah kecelakaan

• mencegah kebakaran dan peledakan

• mencegah gangguan terhadap prosesproduksi dan lingkungan sekitarnya.

• Melindungi manusia dan peralatan akibatkondisi berbahaya

Tujuan sistem Ijin Kerja

• mencegah kecelakaan

• mencegah kebakaran dan peledakan

• mencegah gangguan terhadap prosesproduksi dan lingkungan sekitarnya.

• Melindungi manusia dan peralatan akibatkondisi berbahaya

Manfaat Ijin Kerja

• Perlindungan Tenaga Kerja• Mencegah kerugian akibat kecelakaan• Meningkatkan sikap tanggungjawab dan

disiplin kerja• Perlindungan hukum (claim) jika terjadi

kecelakaan• Sebagai dasar penyelidikan kecelakaan• Sebagai alat kontrol – pengawasan K3• Meningkatkan kinerja K3 perusahaan

• Perlindungan Tenaga Kerja• Mencegah kerugian akibat kecelakaan• Meningkatkan sikap tanggungjawab dan

disiplin kerja• Perlindungan hukum (claim) jika terjadi

kecelakaan• Sebagai dasar penyelidikan kecelakaan• Sebagai alat kontrol – pengawasan K3• Meningkatkan kinerja K3 perusahaan

Safe Work PermitsSafe Work Permits

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:From: M D Y time to M D Y time

Work Description: ____________________________________________________________________________ Supervisor’s Signature Print name________________________________________________________________________________________ Work Order No.

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material ConcentrationTests

Precautions Always Required:

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:From: M D Y time to M D Y time

Work Description: ____________________________________________________________________________ Supervisor’s Signature Print name________________________________________________________________________________________ Work Order No.

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material ConcentrationTests

Precautions Always Required:

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:From: M D Y time to M D Y time

Work Description: ____________________________________________________________________________ Supervisor’s Signature Print name________________________________________________________________________________________ Work Order No.

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material ConcentrationTests

Precautions Always Required:

Safe Work Permit Permit #

Type: (hot work, confined space, line break, etc.... location:

Valid __/___/___ ____ __/___/___ ____ Issued to:From: M D Y time to M D Y time

Work Description: ____________________________________________________________________________ Supervisor’s Signature Print name________________________________________________________________________________________ Work Order No.

Atm Combustible vapors or gases (<10%) Oxygen Concentration (>19.5% & <21%) Toxic Material ConcentrationTests

Precautions Always Required:

Tujuan sistem ijin kerja adalah untuk mengidentifikasisemua bahaya yang berkaitan dengan pekerjaan nonrutin, dan memberikan pengamanan untuk mencegahpotensi bahaya yang timbul

• Melindungi peralatan dari kerusakan• Mencegah bahaya kebakaran• Memastikan pekerjaan dilakukan dengan

cara yang aman• Memberikan arahan mengenai cara yang

aman dalam melaksanakan pekerjaan

Sasaran Permit System

• Melindungi peralatan dari kerusakan• Mencegah bahaya kebakaran• Memastikan pekerjaan dilakukan dengan

cara yang aman• Memberikan arahan mengenai cara yang

aman dalam melaksanakan pekerjaan

WORK PERMIT REQUIREMENT

Permit diperlukan untuk pekerjaan berikut ini:

• Major & Minor Maint. work.• Inspection.• Construction.• Alteration.• Process Equip. cleaning• Entry into confined space.• Excavation• Vehicle entry into hazardous areas etc.

Permit diperlukan untuk pekerjaan berikut ini:

• Major & Minor Maint. work.• Inspection.• Construction.• Alteration.• Process Equip. cleaning• Entry into confined space.• Excavation• Vehicle entry into hazardous areas etc.

Jenis Ijin Kerja1. Ijin Kerja Panas – Hot Work Permit2. Ijin Kerja Dingin – Cold work Permit3. Ijin kerja penggalian _ Digging Permit4. Ijin Kerja Masuk Ruang Tertutup – Entry

Permit5. Ijin Kerja Radioaktif6. Ijin Kerja Listrik7. Ijin Kerja di ketinggian8. Dsb.

1. Ijin Kerja Panas – Hot Work Permit2. Ijin Kerja Dingin – Cold work Permit3. Ijin kerja penggalian _ Digging Permit4. Ijin Kerja Masuk Ruang Tertutup – Entry

Permit5. Ijin Kerja Radioaktif6. Ijin Kerja Listrik7. Ijin Kerja di ketinggian8. Dsb.

Prinsip Permit SystemTHE FIRE TETRAHEDRONTHE FIRE TETRAHEDRON

FUEL

TEMPERATURE

Prinsip Ijin Kerja

Bahanbakar

PanasOksigen PanasOksigen

1. Mengendalikan BahanBakar

2. Mengendalikan Panas

3. Mengendalikan Oksigen

Prinsip Ijin Kerja

Bahanbakar

PanasOksigen

Mengendalikan Bahan Bakar

• Mencegah ataumengendalikan adanyasumber bahan bakar

• Boleh menggunakan api

• Menggunakan Ijin KerjaPanas

PanasOksigen

• Mencegah ataumengendalikan adanyasumber bahan bakar

• Boleh menggunakan api

• Menggunakan Ijin KerjaPanas

Ijin Kerja Panas, menggunakan atau menimbulkansumber panas, atau nyala seperti pekerjaanpengelasan, api dapur, sant blasting dll.

Unsur yang dihindarkan adalah adanya sumber bahanbakar dengan melakukan gas test.

Prinsip Ijin Kerja

Bahanbakar

PanasOksigen

Mengendalikan Panas

• Sumber bahan bakar tidakbisa dikendalikan dandapat timbul sewaktu-waktu

• Kendalikan atau cegahadanya/timbulnya sumberpanas atau energi

• Jenis Ijin Kerja Dingin

PanasOksigen

• Sumber bahan bakar tidakbisa dikendalikan dandapat timbul sewaktu-waktu

• Kendalikan atau cegahadanya/timbulnya sumberpanas atau energi

• Jenis Ijin Kerja DinginIjin Kerja Dingin, adalah pekerjaan yang tidak atautidak boleh menimbulkan adanya sumber panas ataupercikan api.

Sumber bahan bakar diperkirakan timbul setiap saat

Contoh pekerjaan menggunakan palu di tanki minyak

Prinsip Ijin Kerja

Bahanbakar

PanasOksigen

Mengendalikan Oksigen

• Kadar Oksigendiperkirakan tidak amanbagi manusia atau untukkelangsungan prosespembakaran (segi tiga api)

• Ijin Masuk ruang tertutupPanasOksigen

• Kadar Oksigendiperkirakan tidak amanbagi manusia atau untukkelangsungan prosespembakaran (segi tiga api)

• Ijin Masuk ruang tertutup

Ijin Kerja Ruang tertutup dimana kadar oksigen harusdiperhitungkan untuk keselamatan pekerja

Sistem Ijin KerjaPihak yang terlibat dalam sistem ijin kerja

IssuingAuthority

SafetyAdvisor

PerrformingAuthority

Ijin Kerja

Sistem Ijin KerjaIssuing Authority – Pemberi Ijin

– Yaitu pihak operasi atau pengawasdaerah/peralatan yang bertindak sebagai pihakyang memberikan ijin melaksanakan suatupekerjaan yang menyangkut tempat, alat ataulingkungan

– Issuing Authority adalah :• Pengawas Operasi• Shift superintendent• Kepala pabrik• Pengawas instalasi dll

Issuing Authority – Pemberi Ijin

– Yaitu pihak operasi atau pengawasdaerah/peralatan yang bertindak sebagai pihakyang memberikan ijin melaksanakan suatupekerjaan yang menyangkut tempat, alat ataulingkungan

– Issuing Authority adalah :• Pengawas Operasi• Shift superintendent• Kepala pabrik• Pengawas instalasi dll

Sistem Ijin KerjaIssuing Authority – Pemberi Ijin– Tugas dan tanggungjawab

• Memebebaskan semua perlatan dan prosesyang berkaitan dengan pekerjaan darisemua sumber bahaya dan energi sehinggaaman untuk dikerjakan.

• Mengamankan peralatan, tempat kerja danproses untuk keamanan pekerjaan,termasuk memasang sorokan,membersihkan alat, menyetop kegiatansementara waktu, melakukan isolasi sumberenergi dsb.

Issuing Authority – Pemberi Ijin– Tugas dan tanggungjawab

• Memebebaskan semua perlatan dan prosesyang berkaitan dengan pekerjaan darisemua sumber bahaya dan energi sehinggaaman untuk dikerjakan.

• Mengamankan peralatan, tempat kerja danproses untuk keamanan pekerjaan,termasuk memasang sorokan,membersihkan alat, menyetop kegiatansementara waktu, melakukan isolasi sumberenergi dsb.

Sistem Ijin KerjaPerforming Authority – Penerima ijin– Yaitu pihak yang melaksanakan

pekerjaan yang menyangkut suatu alat,tempat kerja atau fasilitas

– Pelaksanaa Pekerjaan :• Bagian pemeliharaan• Bagian teknik sipil, listrik atau mekanik• Pekerja telekomunikasi• Pekerja pembersihan dll

Performing Authority – Penerima ijin– Yaitu pihak yang melaksanakan

pekerjaan yang menyangkut suatu alat,tempat kerja atau fasilitas

– Pelaksanaa Pekerjaan :• Bagian pemeliharaan• Bagian teknik sipil, listrik atau mekanik• Pekerja telekomunikasi• Pekerja pembersihan dll

Sistem Ijin KerjaPerforming Authority – Penerima ijinTugas dan tanggung jawab :

• Melaksanakan pekerjaan dilakukandengan cara yang aman menyangkutpekerja, peralatan dan metodapelaksanaan.

• Mematuhi semua rekomendasi yangdikeliuarkan oleh pemberi ijin dan bagianK3

• Mengawasoi secara langsung selamakegiatan kerja berlangsung dan segeramengambil tindakan jika ditemukankondisi berbahaya

Performing Authority – Penerima ijinTugas dan tanggung jawab :

• Melaksanakan pekerjaan dilakukandengan cara yang aman menyangkutpekerja, peralatan dan metodapelaksanaan.

• Mematuhi semua rekomendasi yangdikeliuarkan oleh pemberi ijin dan bagianK3

• Mengawasoi secara langsung selamakegiatan kerja berlangsung dan segeramengambil tindakan jika ditemukankondisi berbahaya

Sistem Ijin KerjaUnsur Pengawas Keselamatan– Yaitu pihak yang bertanggungjawab

memberikan saran dan petunjuk sertapengawasan keselamatan selamapekerjaan berlangsung

– Unsur pengawasan terdiri atas :• Fungsi K3 perusahaan• Fungsi Listrik• Fungsi Inspeksi• Fungsi Telekomunikasi• Dll yang diperlukan

Unsur Pengawas Keselamatan– Yaitu pihak yang bertanggungjawab

memberikan saran dan petunjuk sertapengawasan keselamatan selamapekerjaan berlangsung

– Unsur pengawasan terdiri atas :• Fungsi K3 perusahaan• Fungsi Listrik• Fungsi Inspeksi• Fungsi Telekomunikasi• Dll yang diperlukan

Sistem Ijin KerjaUnsur Pengawas Keselamatan– Tugas dan tanggungjawab

• Melaksanakan monitoring selamapekerjaan berlangsung

• Meneliti dan meyakinkan bahwa semuasyarat keselamatan telah dipenuhi

• Memberikan rekomendasi cara kerja yangaman

• Melaksanakan pengetesan gasberbahaya

• Menghentikan pekerjaan jika dinilaikondisi keselamatan tidak terjamin atauterjadi pelanggaran prosedur

Unsur Pengawas Keselamatan– Tugas dan tanggungjawab

• Melaksanakan monitoring selamapekerjaan berlangsung

• Meneliti dan meyakinkan bahwa semuasyarat keselamatan telah dipenuhi

• Memberikan rekomendasi cara kerja yangaman

• Melaksanakan pengetesan gasberbahaya

• Menghentikan pekerjaan jika dinilaikondisi keselamatan tidak terjamin atauterjadi pelanggaran prosedur

Ijin Kerja Panas• Semua pekerjaan yang menggunakan atau

menimbulkan energi panas atau bunga api yangmemiliki cukup energi untuk proses pembakaran.

• Jenis pekerjaan panas :– Pengelasan– merokok, menyalakan api dapur,, korek api– Menghidupkan kendaraan dengan internal

combustion engine di daerah berbahaya gas– sand blasting– Penggunaan alat pneumatik– Peralatan listrik– dll

• Semua pekerjaan yang menggunakan ataumenimbulkan energi panas atau bunga api yangmemiliki cukup energi untuk proses pembakaran.

• Jenis pekerjaan panas :– Pengelasan– merokok, menyalakan api dapur,, korek api– Menghidupkan kendaraan dengan internal

combustion engine di daerah berbahaya gas– sand blasting– Penggunaan alat pneumatik– Peralatan listrik– dll

Ijin Kerja PanasPersyaratan Utama• Harus bebas gas (gas free)• Bebas dari sumber bahaya dari

lingkungan, minimal dalam radius 25meter

• Dilaksanakan pemeriksaan gas secaraberkala

Persyaratan Utama• Harus bebas gas (gas free)• Bebas dari sumber bahaya dari

lingkungan, minimal dalam radius 25meter

• Dilaksanakan pemeriksaan gas secaraberkala

Ijin Kerja Panas

Tindakan pengamanan (safety precaution)• Memeriksa kondisi gas berbahaya setiap

saat• Mengisolir dan mengamankan semua

sumber bahan bakar seperti perpipaan,parit terbuka, venting dsb

• Memasang tirai air untuk pengamanansumber panas

Tindakan pengamanan (safety precaution)• Memeriksa kondisi gas berbahaya setiap

saat• Mengisolir dan mengamankan semua

sumber bahan bakar seperti perpipaan,parit terbuka, venting dsb

• Memasang tirai air untuk pengamanansumber panas

Ijin Kerja Dingin• Semua pekerjaan yang tidak menggunakan

sumber panas atau tidak diperkenankanmenimbulkan sumber panas.

• Jenis pekerjaan Dingin :– Menggunakan martil besi didaerah gas (tindakan anti

bunga api)– Mengecat di daerah berbahaya– Perbaikan pompa atau peralatan proses yang sedang

beroperasi– Menggali di daerah unit proses– dll

• Semua pekerjaan yang tidak menggunakansumber panas atau tidak diperkenankanmenimbulkan sumber panas.

• Jenis pekerjaan Dingin :– Menggunakan martil besi didaerah gas (tindakan anti

bunga api)– Mengecat di daerah berbahaya– Perbaikan pompa atau peralatan proses yang sedang

beroperasi– Menggali di daerah unit proses– dll

Ijin Kerja Dingin• Persyaratan

– Tidak boleh timbul sumber api (percikan, bunga apidsb)

– Harus dilakukan tindakan anti bunga api, misalnyadengan membasahkan peralatan dengan air,penggunaan martil tembaga atau kuningan dsb

– Diperlukan tindakan waspada karena adanya sumbergas berbahaya tidak dapat dikendalikan misalnyabekerja di lingkungan unit proses yang sedangberoperasi

– Semua peralatan kerja harus diamankan darikemungkinan terjadinya percikan bunga api.

• Persyaratan– Tidak boleh timbul sumber api (percikan, bunga api

dsb)– Harus dilakukan tindakan anti bunga api, misalnya

dengan membasahkan peralatan dengan air,penggunaan martil tembaga atau kuningan dsb

– Diperlukan tindakan waspada karena adanya sumbergas berbahaya tidak dapat dikendalikan misalnyabekerja di lingkungan unit proses yang sedangberoperasi

– Semua peralatan kerja harus diamankan darikemungkinan terjadinya percikan bunga api.

Ijin Kerja Ruang Tertutup• Bekerja di lingkungan dengan kadar oksigen tidak

memadai• Contoh :

– Masuk dan bekerja dalam tangki bekas berisi bahancair mudah terbakar

– Bekerja dalam ruangan dengan ventiliasi terbatas

• Bekerja di lingkungan dengan kadar oksigen tidakmemadai

• Contoh :– Masuk dan bekerja dalam tangki bekas berisi bahan

cair mudah terbakar– Bekerja dalam ruangan dengan ventiliasi terbatas

Ijin Kerja Penggalian• Diperlukan untuk pekerjaan yang

melakukan galian tanah :– Penggalian jalur pipa– Penggalian tanah untuk konstruksi– dll

Safe Work PermitsSafe Work Permits

Excavations may expose hazardous materials, which have leaked and arecontaminating the soil.

Permits ensure that procedures to protect workers from exposure to toxicsubstances have been identified.

Ijin Kerja Listrik• Untuk melindungi pekerjaan yang

menggunakan peralatan listrik ataubekerja pada lingkungan peralatan atausarana pembangkit dan penyalur listrik

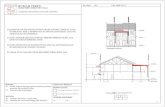

PREPARATION OFWORKPERMIT

PREPARATION OF THE EQUIPMENT

• Equipment electrically isolated• Inspection tested(for cold & hot job)• Isolated from steam,air & gas• Depressurized• Drained• Positively isolated/blinded• Steamed & water flushed

• Equipment electrically isolated• Inspection tested(for cold & hot job)• Isolated from steam,air & gas• Depressurized• Drained• Positively isolated/blinded• Steamed & water flushed

PREPARATION OF EQUIP. CONTD.

• Ventilated & gas freed• Continuous inert gas flow / continuous

adequate ventilation arranged.• Vehicle/equipment in good condition with

spark arrested• Radiation source removed(Confined space

entry)

• Ventilated & gas freed• Continuous inert gas flow / continuous

adequate ventilation arranged.• Vehicle/equipment in good condition with

spark arrested• Radiation source removed(Confined space

entry)

PREPARATION OF EQUIP. CONTD.

• Ventilated & gas freed• Continuous inert gas flow / continuous

adequate ventilation arranged.• Vehicle/equipment in good condition with

spark arrested• Radiation source removed(Confined space

entry)

• Ventilated & gas freed• Continuous inert gas flow / continuous

adequate ventilation arranged.• Vehicle/equipment in good condition with

spark arrested• Radiation source removed(Confined space

entry)

RESIDUAL HAZARDS• Lack of oxygen• H2S and/or any other toxic gases• Combustible gases• Corrosive chemicals• Steam / Condensate• Pyrophoric iron• High humidity

• Lack of oxygen• H2S and/or any other toxic gases• Combustible gases• Corrosive chemicals• Steam / Condensate• Pyrophoric iron• High humidity

RESIDUAL HAZARDS• Lack of oxygen• H2S and/or any other toxic gases• Combustible gases• Corrosive chemicals• Steam / Condensate• Pyrophoric iron• High humidity

• Lack of oxygen• H2S and/or any other toxic gases• Combustible gases• Corrosive chemicals• Steam / Condensate• Pyrophoric iron• High humidity

PROTECTION MEASURES• Protective clothing• Hearing protection• Safety Harness• Eye protection• Face protection• Respiratory protection• Keep fire equipment stand-by

• Protective clothing• Hearing protection• Safety Harness• Eye protection• Face protection• Respiratory protection• Keep fire equipment stand-by

PROTECTIVE MEASURES CONTD.

• Barricade the area• Remove flammable and combustible• Cover with fire retardant tarpaulin• Crane with basket stand-by• Attendance with Airline set• keep man ways open• Allow minimum possible no. of persons inside

confined space

• Barricade the area• Remove flammable and combustible• Cover with fire retardant tarpaulin• Crane with basket stand-by• Attendance with Airline set• keep man ways open• Allow minimum possible no. of persons inside

confined space

PROTECTIVE MEASURESCONTD.

• To ensure positive isolation & maintain itall through

• Ensure adequate ventilation all through• Display copy of entry permit near entry

manhole

• To ensure positive isolation & maintain itall through

• Ensure adequate ventilation all through• Display copy of entry permit near entry

manhole

GAS TEST FOR WORK PERMIT

Why gas test is required ?• Most of the gases are unwanted

Hazards involved -• Flammability(Fire & Explosion)• Toxicity(health hazard)• Oxygen Deficiency

Why gas test is required ?• Most of the gases are unwanted

Hazards involved -• Flammability(Fire & Explosion)• Toxicity(health hazard)• Oxygen Deficiency

Common flammable gases/liquids inrefinery are -

• All petroleum products,Crude andintermediates

• Hydrogen• LPG• Common toxic gases in refinery -• H2S, CO,NH3,CL2, etc.

GAS TEST FOR WORK PERMIT

Common flammable gases/liquids inrefinery are -

• All petroleum products,Crude andintermediates

• Hydrogen• LPG• Common toxic gases in refinery -• H2S, CO,NH3,CL2, etc.

COMMON TERMINOLOGIES :For flammable substances:• Flash Point :

Minimum temp. at which a liquid gives offsufficient vapor to form an ignitable mix. Itwill give a flash, flame will not continue.

Auto Ignition Temp.:The lowest temp. to which a substance willignite without a spark or flame.

GAS TEST FOR WORK PERMITCOMMON TERMINOLOGIES :For flammable substances:• Flash Point :

Minimum temp. at which a liquid gives offsufficient vapor to form an ignitable mix. Itwill give a flash, flame will not continue.

Auto Ignition Temp.:The lowest temp. to which a substance willignite without a spark or flame.

• Explosive limit :The concentration range of vapor inair when propagation offlame(ignition) occurs in presence ofan ignition source.

• LEL (Lower Explosive Limit) :The minimum concentration of vaporto air required to propagate(ignite)flame.

GAS TEST FOR WORK PERMIT

• Explosive limit :The concentration range of vapor inair when propagation offlame(ignition) occurs in presence ofan ignition source.

• LEL (Lower Explosive Limit) :The minimum concentration of vaporto air required to propagate(ignite)flame.

• UEL(Upper Explosive Limit) :The maximum vapor to air conc.abovewhich propagation of a flame will notoccur(will not ignite).

GAS TEST FOR WORK PERMIT

Material LEL UEL F Pt.(C) AIT(C)Hydrogen 4 75 Gas 585Methane 5 15 Gas 538Propane 2 9.5 - 104 466Naphtha 1.1 5.9 - 18 288ATK/ATF 0.7 5.0 35-50 210Diesel 0.7 5.0 32-96 256Fuel Oil 1 5.0 66 262-407

GAS TEST FOR WORK PERMIT

Material LEL UEL F Pt.(C) AIT(C)Hydrogen 4 75 Gas 585Methane 5 15 Gas 538Propane 2 9.5 - 104 466Naphtha 1.1 5.9 - 18 288ATK/ATF 0.7 5.0 35-50 210Diesel 0.7 5.0 32-96 256Fuel Oil 1 5.0 66 262-407

GAS TEST CONTD.

Toxic substances :TLV (Threshold Limit Value / PEL(PermissibleExposure Limit) :

The maximum permissible conc. of a toxicsubstance to which exposure of a person willhave no adverse effect on health for working 8hrs per day.

STEL(Short Term Exposure Limit) :Maximum conc. to which worker can be exposedfor a period of 15 mins. without any adverseeffect to health.

Toxic substances :TLV (Threshold Limit Value / PEL(PermissibleExposure Limit) :

The maximum permissible conc. of a toxicsubstance to which exposure of a person willhave no adverse effect on health for working 8hrs per day.

STEL(Short Term Exposure Limit) :Maximum conc. to which worker can be exposedfor a period of 15 mins. without any adverseeffect to health.

GAS TEST CONTD.

IDLH(Immediate Danger to Life & Health)• A maximum conc. from which one can

escape within 30 mins. without irreversiblehealth effect.

• HYDROGEN SULPHIDE (H2S)Highly toxic, combustible, colorless.Smells like rotten egg.

IDLH(Immediate Danger to Life & Health)• A maximum conc. from which one can

escape within 30 mins. without irreversiblehealth effect.

• HYDROGEN SULPHIDE (H2S)Highly toxic, combustible, colorless.Smells like rotten egg.

GAS TEST - H2S

EFFECTS ON HUMAN BODYPHYSICAL EFFECT CONC.(PPM)Can be smelled as rotten egg 0.13TLV 10STEL 15Smelling sense will dry within 150 - 2002 mins, burning sensation ineye & throat

EFFECTS ON HUMAN BODYPHYSICAL EFFECT CONC.(PPM)Can be smelled as rotten egg 0.13TLV 10STEL 15Smelling sense will dry within 150 - 2002 mins, burning sensation ineye & throat

GAS TEST - H2S CONTD.PHYSICAL EFFECT CONC(PPM)IDLH(Loss of smelling sense, 300heavy breathing, dizziness,headache,and total collapsewithin 1 to 4 Hrs)Dizziness,headache,lungs 450problem and total collapse within 30 to60 mins.

PHYSICAL EFFECT CONC(PPM)IDLH(Loss of smelling sense, 300heavy breathing, dizziness,headache,and total collapsewithin 1 to 4 Hrs)Dizziness,headache,lungs 450problem and total collapse within 30 to60 mins.

GAS TEST-H2S CONTD.PHYSICAL EFFECT CONC(PPM)Slow down of heart beats, 700heavy breathing with coughing,then death, if not rescued

Fatal emergency over 700

Explosive limits : 4.6 to 46%, it gives blue flamewhen ignited.

PHYSICAL EFFECT CONC(PPM)Slow down of heart beats, 700heavy breathing with coughing,then death, if not rescued

Fatal emergency over 700

Explosive limits : 4.6 to 46%, it gives blue flamewhen ignited.

GAS TEST-H2S CONTD.

FIRST AID :IF INHALED -Remove exposed person to fresh air andadminister oxygen immediately.

PROTECTION:Use fresh air mask in case conc. exceeds10 PPM

FIRST AID :IF INHALED -Remove exposed person to fresh air andadminister oxygen immediately.

PROTECTION:Use fresh air mask in case conc. exceeds10 PPM

TOXIC GAS - COTOXIC AS WELL AS FLAMMABLETLV - 50 PPMSTEL - 400 PPMIDLH - 1500 PPMLEL - 12.5%UEL - 74 %

TOXIC AS WELL AS FLAMMABLETLV - 50 PPMSTEL - 400 PPMIDLH - 1500 PPMLEL - 12.5%UEL - 74 %

GAS TEST - COHEALTH HAZARDS:CO combines with hemoglobin of blood andmake it unable to carry oxygen.

Symptoms : Headache, dizziness tounconscious and ultimately death.

First Aid :Remove to fresh air and apply oxygen at theearliest.

HEALTH HAZARDS:CO combines with hemoglobin of blood andmake it unable to carry oxygen.

Symptoms : Headache, dizziness tounconscious and ultimately death.

First Aid :Remove to fresh air and apply oxygen at theearliest.

OTHER TOXIC GASESTOXIC GAS TLV STEL IDLH

NH3 25 35 -SO2 2 5 -CL2 0.5 1 30

TOXIC GAS TLV STEL IDLH

NH3 25 35 -SO2 2 5 -CL2 0.5 1 30

GAS TEST CONTD.

For hot work the gas test results shall be :• Combustible - Below 1 % LEL

( Preferably NIL)For confined space entry :• Oxygen - 19.5% minimum• Combustible - 10 % LEL Max.• Toxic gases - below TLV

For hot work the gas test results shall be :• Combustible - Below 1 % LEL

( Preferably NIL)For confined space entry :• Oxygen - 19.5% minimum• Combustible - 10 % LEL Max.• Toxic gases - below TLV

GAS TEST CONTD.

Confined space With BA protection :• Combustible - 20% of LEL maximum• H2S - Less than 100 PPM• CO - Less than 500 PPMHowever, no hot job can be carried out

inside the confined space at thiscondition.

Confined space With BA protection :• Combustible - 20% of LEL maximum• H2S - Less than 100 PPM• CO - Less than 500 PPMHowever, no hot job can be carried out

inside the confined space at thiscondition.

WORKS NEED GAS TEST• Gas tests are required for all hot

work/vehicle entry and confined spaceentry permits & some cold permits also.

• Issuing authority shall determine therequirement of gas test & frequency ofre-checking.

• Trained Gas tester only shall carry outthe test.

• Gas tests are required for all hotwork/vehicle entry and confined spaceentry permits & some cold permits also.

• Issuing authority shall determine therequirement of gas test & frequency ofre-checking.

• Trained Gas tester only shall carry outthe test.

RESPONSIBILIES OF GASTESTING AUTHORITY

• To check & confirm that the gastesting instrument is working inperfect condition before proceedingfor the area/equipment

• To carry out gas test at all criticallocations/positions

• To advise on safe method to workinside/at the location i.e., furthergas freeing , use of PPE etc.

• To check & confirm that the gastesting instrument is working inperfect condition before proceedingfor the area/equipment

• To carry out gas test at all criticallocations/positions

• To advise on safe method to workinside/at the location i.e., furthergas freeing , use of PPE etc.

ELECTRICAL ISOLATION• Before issuing a Work Permit, it is

essential to ensure that the equipment /facility to be worked on is electricallysafe and electrical power is isolated tothe extent necessary for the safeconduct of the authorized work.

• Issuing, Executing authorities andElectrical Maintenance shall jointlydecide the extent of isolation required.

• Before issuing a Work Permit, it isessential to ensure that the equipment /facility to be worked on is electricallysafe and electrical power is isolated tothe extent necessary for the safeconduct of the authorized work.

• Issuing, Executing authorities andElectrical Maintenance shall jointlydecide the extent of isolation required.

SPECIAL REQUIREMENT FOR -WORKING WITH RADIOGRAPHY

• Risk assessment through checklist• Barricade the area and provide adequate warning

signs.• Film badges and Dosimeters shall be worn by

personnel handling radiography equip.• job preferably during night time or with least or no

person around.• Continuous monitoring of cordoned off area

SPECIAL REQUIREMENT FOR -WORKING WITH RADIOGRAPHY

• Risk assessment through checklist• Barricade the area and provide adequate warning

signs.• Film badges and Dosimeters shall be worn by

personnel handling radiography equip.• job preferably during night time or with least or no

person around.• Continuous monitoring of cordoned off area

SPECIAL REQUIREMENTS FOR HOT WORK

• The person who authorizes the Hot WorkPermit is responsible for ensuring that the siteand the equipment are properly prepared toprevent the danger of fire & explosion involvingflammable material.

• The equipment shall be emptied and cleanedof flammable materials and isolated fromsources of hydrocarbons by means ofdisconnection, blanking or insertion of blinds.

• The person who authorizes the Hot WorkPermit is responsible for ensuring that the siteand the equipment are properly prepared toprevent the danger of fire & explosion involvingflammable material.

• The equipment shall be emptied and cleanedof flammable materials and isolated fromsources of hydrocarbons by means ofdisconnection, blanking or insertion of blinds.

• Equipment and surrounding areas shall be checkedto ensure that they are free from any combustiblegas.Carry out gas test.

• Any heavy oil deposit, dried vegetation or otherflammable / combustible materials within 8 m of a hotwork site shall be cleared away.

• No hot work shall be allowed within a radius of 15 mof any sample point, drain or relief valve outlet unlessprecautions have been taken to prevent the escapeof flammable liquids and vapors.

• Equipment and surrounding areas shall be checkedto ensure that they are free from any combustiblegas.Carry out gas test.

• Any heavy oil deposit, dried vegetation or otherflammable / combustible materials within 8 m of a hotwork site shall be cleared away.

• No hot work shall be allowed within a radius of 15 mof any sample point, drain or relief valve outlet unlessprecautions have been taken to prevent the escapeof flammable liquids and vapors.

• The outlet of all units drain seals within 15 m of thehot work shall be plugged.

• If welding or grinding is to be done at height, thenprecautions shall be taken to prevent the spread ofsparks and molten metal to the surrounding of thework area with fire-resisting or flame-retardingtarpaulin.

• A hose capable of reaching up to the hot work pointand connected to fire water main.

• Fire Station (333/5989) shall be informed of hotwork.

• The outlet of all units drain seals within 15 m of thehot work shall be plugged.

• If welding or grinding is to be done at height, thenprecautions shall be taken to prevent the spread ofsparks and molten metal to the surrounding of thework area with fire-resisting or flame-retardingtarpaulin.

• A hose capable of reaching up to the hot work pointand connected to fire water main.

• Fire Station (333/5989) shall be informed of hotwork.

VALIDITY OF PERMIT

• Work permit shall be initially issued for aperiod of 8 hrs. and shall be renewed forone more shift .

• On need basis , permit can be given formax. 7 days period.

• Clearance to be obtained every shift.• Clearance to be given after physically

checking the site.

• Work permit shall be initially issued for aperiod of 8 hrs. and shall be renewed forone more shift .

• On need basis , permit can be given formax. 7 days period.

• Clearance to be obtained every shift.• Clearance to be given after physically

checking the site.