GARIS PANDUAN PENJADUALAN...

Transcript of GARIS PANDUAN PENJADUALAN...

1 / 6

GARIS PANDUAN PENJADUALAN KERJA Kaedah Membina Work Breakdown Structure (WBS) Bagi Projek Dalam Pembinaan

Unit Amalan Terbaik

Bahagian Pengurusan Projek Kompleks

Cawangan Perancangan Aset Bersepadu

JKR Malaysia

Disember 2018

2 / 6

KANDUNGAN

1. PENDAHULUAN .. 3 2. PROGRAM KERJA SEPINTAS LALU .. 3 3. WORK BREAKDOWN STRUCTURE (WBS) .. 4 4. TEMPLAT WBS .. 6 5. RUJUKAN .. 6 6. APPENDIKS

APPENDIKS A : TEMPLAT WBS BAGI PROJEK BANGUNAN APPENDIKS B : TEMPLAT WBS BAGI PROJEK JALAN

3 / 6

1 PENDAHULUAN

Garis panduan ini diwujudkan sebagai panduan kepada

pegawai JKR dan Kontraktor projek dalam membina

sebuah program kerja yang selari dengan kehendak-

kehendak Jabatan. Panduan ini juga merupakan

kesinambungan daripada ‘Work Program Guidelines’

yang telah diterbitkan oleh Cawangan Pengurusan Projek

Kompleks pada Ogos 2011.

Panduan ini lebih TERTUMPU kepada kaedah mengatur

aktiviti supaya terjadual mengikut keadaan sebenar

pembinaan di tapak bina.

2 PROGRAM KERJA SEPINTAS LALU

Program Kerja adalah sebuah alat pengurusan projek yang menggambarkan kerja-kerja

yang perlu dilakukan, siapa yang akan melaksanakan kerja (sumber) dan bila kerja tersebut

perlu dilakukan. Pengunaan program kerja yang tepat di dalam pengurusan projek akan

memberi kelebihan kepada Pasukan Projek dari segi :-

• Memberi peluang untuk merancang dan mengadakan analisis strategik di

peringkat permulaan projek;

• Memfokuskan kepada matlamat projek;

• Memberi indikator apabila Pasukan Projek berada di luar trek;

• Memudahkan pelaporan projek;

• Mengesan masalah pada peringkat awal samada untuk mencegah,

meminimumkan dan/atau mengurangkan kesan masalah terhadap jadual projek;

dan

• Membolehkan pengurus projek menguasai pengendalian projek.

4 / 6

Maka tujuan Program Kerja diadakan adalah untuk menyediakan ‘road map’ yang berguna

untuk digunakan oleh Pasukan Projek dalam :-

• Merancang, memantau, dan mengawal pelaksanaan kerja yang tepat pada

masanya, dari hari projek bermula sehingga projek disiapkan;

• Menerap dan memantau kemajuan projek;

• Mengurus sumber dengan lebih lancar;

• Mengenalpasti dan memantau kebolehgantungan dan kekangan antara aktiviti

untuk mengelakkan kelewatan yang boleh dicegah; dan

• Berkomunikasi lebih kerap dan berkesan dengan pihak berkepentingan.

Justeru, menubuhkan program kerja yang realistik adalah salah satu tindakan awal yang

kritis dalam mengendalikan sesebuah projek. Apabila program kerja itu jelas dan terperinci,

ia memudahkan pasukan projek memahami pakej kerja (Work Breakdown Structure) seiring

dengan sumber, tugas dan tanggungjawab, tarikh permulaan dan akhir setiap tugas, dan

jangka masa tugas yang diharapkan.

3 WORK BREAKDOWN STRUCTURE (WBS)

Sebelum mewujudkan sebuah program kerja, perancang program (planner/scheduler) harus

memahami skop projek, kaedah pelaksanaan projek, tempoh masa yang diperlukan, kadar

produktiviti bagi sesuatu tugas, senarai sumber dan ketersediaan setiap sumber tersebut.

3.1 STRUKTUR WBS

WBS adalah penguraian hierarki dari

keseluruhan skop kerja yang akan

dijalankan bagi mencapai objektif

projek. WBS hendaklah

distrukturkan mengikut cara kerja

yang akan dilaksanakan di tapak dan

mencerminkan kaedah pelaporan

projek yang akan digunakan.

5 / 6

Terdapat perlbagai kaedah pengstrukturan kerja dalam menguraikan sesuatu skop projek.

Struktur yang paling umum adalah struktur yang mengandungi 4 tingkat struktur utama.

Tiga peringkat yang pertama adalah tahap pengurusan projek yang boleh dikawal, seperti

nama projek, fasa projek, jumlah blok dan komponen utama projek. Manakala peringkat

yang lebih rendah mengandungi aktiviti yang lebih teknikal di dalam sesuatu projek.

3.2 Pakej Kerja Dalam WBS

WBS mengandungi beberapa elemen yang berperingkat. Setiap elemen dibahagikan

kepada beberapa pakej kerja mengikut bidang kerja yang mudah diurus. WBS disusun

mengikut Pakej Kerja yang sama supaya memudahkan pemantauan aktiviti dilaksanakan.

Pakej Kerja merupakan peringkat terendah bagi sesuatu cawangan WBS. Ia ditakrif sebagai

seksyen kerja yang menghasilkan output sama (Rajah 1). Pakej Kerja mestilah pada tahap

terperinci, cukup kecil sehingga membolehkan perancangan, pengurusan dan kawalan yang

berkesan dijalankan terhadap kerja yang bakal dilaksanakan. Menurut JKR ‘Work Program

Guidelines’, pada tahap ini setiap aktiviti boleh diukur dan dikawal dari segi masa, kos,

sumber dan kualiti.

Rajah 1 : Struktur & Aras WBS minima mengikut ‘JKR Work Program Guidelines’

LEVEL 4

LEVEL 3

LEVEL 2

LEVEL 1 Nama Projek

1.1

1.1.1

1.1.1.1 Pakej Kerja

1.1.2

1.1.2.1 Pakej Kerja

1.2

1.2.1

1.2.1.1 Pakej Kerja

1.2.1.2 Pakej Kerja

6 / 6

4 TEMPLAT WBS

Templat WBS ini disediakan dalam 2 jenis iaitu WBS Projek Bangunan dan WBS Projek

Jalan. Templat ini bertujuan untuk memperjelaskan lagi struktur WBS yang disaran

digunakan dalam pemantauan projek.

Walaubagaimanapun templat ini adalah panduan dan rujukan sahaja. Ia tidak mempunyai butiran seperti tempoh masa, sumber dan lain-lain. WBS yang dinyatakan boleh ditambah atau dikurangkan mengikut kesesuaian. Justeru setiap WBS yang dibina perlulah mengikut skop projek dan kaedah pembinaan yang digunakan di tapak bina untuk sesuatu projek itu.

Templat ini disediakan di Appendiks 1 (Bangunan) dan Appendiks 2 (Jalan).

5 RUJUKAN

i. Surat Arahan KPKR Bil. 15/2014

ii.. Surat Arahan Pengarah Kanan CKUB bertarikh 10 April 2017

Disediakan oleh;

Unit Amalan Terbaik

Bahagian Pengurusan Projek Kompleks

Cawangan Perancangan Aset Bersepadu

Jabatan Kerja Raya Malaysia

Disember 2018

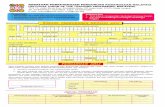

APPENDIKS A Templat WBS Bagi Projek Bangunan

ID WBS Task Name Duration Start

1 1 PROJECT BUILDING

2 1.1 Site Possession

3 1.2 PRELIMINARIES

4 1.2.1 Performance Bond

5 1.2.2 Insurance of Works

6 1.2.3 Project Signboard

7 1.2.4 Site Site Survey & Setting Out

8 1.2.5 Work Program

9 1.2.6 Temporary Diversion and Relocation of Existing Overhead And Underground Services

10 1.2.7 Construction Plan

11 1.2.8 Contractor's Plant

12 1.2.9 Temporary Water and Power Supplies For The Works

13 1.2.10 Site Security

14 1.2.11 Temporary Access And Maintenance Of Existing Roads

15 1.2.12 Control of Workmen, Plant And Machinery At Site

16 1.2.13 Contractor's Temporary Accomadation And Facilities For Workmen Living On Site

17 1.2.14 Contractor's Office And Storage

18 1.2.15 Care And Protection Of Materials And Works

19 1.2.16 Progress Photographs

20 1.2.17 Material Testing Laboratory And Staff

21 1.2.18 Office Accomadation For SO

22 1.2.19 Telephone For SO

23 1.2.20 Survey Instruments And Personnel

24 1.2.21 Site Items For SO / Office Equipments And Facilities

25 1.2.22 Safe Working Area

26 1.2.23 Safety, Health And Welfare

27 1.2.24 Keeping The Site Tidy

28 1.2.25 Coordination Of Mechanical And Electrical ( M & E) Services

29 1.2.26 Site Agents And Assistants

30 1.3 DEMOLITION WORKS

31 1.3.1 Submission and approval of method statement

32 1.3.2 Existing Building

33 1.3.2.1 Demolition including all underground structure

34 1.3.2.2 Removal from site

35 1.3.3 Existing Physical Facilities

36 1.3.3.1 Demolition including all underground structure

37 1.3.3.2 Removal from site

38 1.3.4 Existing Services eg. Septic Tank

39 1.3.4.1 Demolition including all underground structure

40 1.3.4.2 Removal from site

41 1.4 SITE CLEARANCE AND EARTHWORKS

42 1.4.1 Temporary Works

43 1.4.1.1 Wash through

44 1.4.1.2 Temporary earth drain

45 1.4.1.3 Silt trap and emergency spillway

46 1.4.2 Setting Out

47 1.4.3 Site Clearing

48 1.4.4 Earthworks

49 1.4.4.1 Excavate of top soil and remove surplus from site

50 1.4.4.2 Excavation to formation level

51 1.4.4.3 Earthfilling with approved surplus excavated soil

52 1.4.4.4 Earthfilling with imported materials

53 1.4.4.5 Sand Blanket

54 1.4.5 Cut and Fill

55 1.4.5.1 Cut

56 1.4.5.2 Excavation to formation level

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A1

ID WBS Task Name Duration Start

57 1.4.5.3 Removal from site

58 1.4.5.4 Fill

59 1.4.5.5 Earthfilling with approved surplus excavated soil

60 1.4.5.6 Earthfilling with imported materials

61 1.4.5.7 Sand Blanket

62 1.4.6 Geotechnical Works

63 1.4.6.1 Supply non-woven geotextile

64 1.4.6.2 Lay non-woven geotextile

65 1.5 SLOPE PROTECTION

66 1.5.1 Turfing

67 1.5.1.1 Close Turfing to Slope

68 1.5.1.2 Spot Turfing to Slope

69 1.5.2 RE Wall

70 1.5.3 RC Wall

71 1.5.4 Sheet Pile

72 1.5.5 Guniting

73 1.5.6 Gabion

74 1.5.7 Anchor wall

75 1.5.8 Embankment

76 1.6 BUILDING WORKS

77 1.6.1 Blok A

78 1.6.1.1 Submission of Method Statements / Samples / Materials

79 1.6.1.2 Approval

80 1.6.1.3 SUB STRUCTURE

81 1.6.1.3.1 PILING

82 1.6.1.3.1.1 P.C Spun Pile / RC Pile

83 1.6.1.3.1.1.1 Survey

84 1.6.1.3.1.1.2 Mobilise

85 1.6.1.3.1.1.3 Test pile

86 1.6.1.3.1.1.4 Load Test

87 1.6.1.3.1.1.4.1 Maintained Load Test

88 1.6.1.3.1.1.4.2 PDA

89 1.6.1.3.1.1.5 Working Pile

90 1.6.1.3.1.1.6 Cutting off pile head

91 1.6.1.3.1.1.7 Concreting works

92 1.6.1.3.1.1.8 As- Built

93 1.6.1.3.1.1.9 Demobilise

94 1.6.1.3.1.2 Micro Pile

95 1.6.1.3.1.2.1 Survey

96 1.6.1.3.1.2.2 Mobilise

97 1.6.1.3.1.2.3 Test pile

98 1.6.1.3.1.2.3.1 Drilled hole with temp.casing

99 1.6.1.3.1.2.3.2 Supply & install permanent casing

100 1.6.1.3.1.2.3.3 Supply & place cement grout

101 1.6.1.3.1.2.3.4 Cutting off pile head

102 1.6.1.3.1.2.4 Load Test

103 1.6.1.3.1.2.4.1 Maintained Load Test

104 1.6.1.3.1.2.4.2 PDA

105 1.6.1.3.1.2.5 Working pile

106 1.6.1.3.1.2.5.1 Drilled hole with temp.casing

107 1.6.1.3.1.2.5.2 Supply & install permanent casing

108 1.6.1.3.1.2.5.3 Supply & place cement grout

109 1.6.1.3.1.2.5.4 Cutting off pile head

110 1.6.1.3.1.2.6 As-Built

111 1.6.1.3.1.2.7 Demobilise

112 1.6.1.3.1.3 Bore Pile

113 1.6.1.3.1.3.1 Survey

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A2

ID WBS Task Name Duration Start

114 1.6.1.3.1.3.2 Mobilise

115 1.6.1.3.1.3.3 Test Pile

116 1.6.1.3.1.3.3.1 Drilled hole with temp.casing

117 1.6.1.3.1.3.3.2 Supply & install permanent casing

118 1.6.1.3.1.3.3.3 Reinforcement

119 1.6.1.3.1.3.3.4 Concreting works

120 1.6.1.3.1.3.3.5 Cutting off pile head

121 1.6.1.3.1.3.4 Load Test

122 1.6.1.3.1.3.4.1 Statnamic test

123 1.6.1.3.1.3.4.2 Penetration test

124 1.6.1.3.1.3.4.3 PDA

125 1.6.1.3.1.3.4.4 Integrity test

126 1.6.1.3.1.3.5 Working Pile

127 1.6.1.3.1.3.5.1 Drilled hole with temp.casing

128 1.6.1.3.1.3.5.2 Supply & install permanent casing

129 1.6.1.3.1.3.5.3 Reinforcement

130 1.6.1.3.1.3.5.4 Concreting works

131 1.6.1.3.1.3.5.5 Cutting off pile head

132 1.6.1.3.1.3.6 As-Built

133 1.6.1.3.1.3.7 Demobilise

134 1.6.1.3.2 Excavate & remove

135 1.6.1.3.3 Soil-Anti Termite Treatment

136 1.6.1.3.4 Pile Cap

137 1.6.1.3.5 Column Stump

138 1.6.1.4 GROUND FLOOR

139 1.6.1.4.1 SUPER STRUCTURE

140 1.6.1.4.1.1 Ground Floor Beam

141 1.6.1.4.1.2 Ground Floor Slab

142 1.6.1.4.1.3 Ground Floor Column

143 1.6.1.4.2 ARCHITECT

144 1.6.1.4.2.1 WALLS

145 1.6.1.4.2.1.1 EXTERNAL WALL

146 1.6.1.4.2.1.1.1 Brickwall / RC Wall

147 1.6.1.4.2.1.1.2 Prepare and apply damp proof course

148 1.6.1.4.2.1.1.3 Coping

149 1.6.1.4.2.1.1.4 Plastering

150 1.6.1.4.2.1.1.5 Finishes

151 1.6.1.4.2.1.1.5.1 Tiles

152 1.6.1.4.2.1.1.5.2 Paint

153 1.6.1.4.2.1.2 INTERNAL WALL

154 1.6.1.4.2.1.2.1 Brickwall / RC Wall

155 1.6.1.4.2.1.2.2 Prepare and apply damp proof course

156 1.6.1.4.2.1.2.3 Partition

157 1.6.1.4.2.1.2.4 Feature Wall

158 1.6.1.4.2.1.2.5 Plastering

159 1.6.1.4.2.1.2.6 Finishes

160 1.6.1.4.2.1.2.6.1 Tiles

161 1.6.1.4.2.1.2.6.2 Paint

162 1.6.1.4.2.2 Door & Window Frame

163 1.6.1.4.2.3 FLOOR

164 1.6.1.4.2.3.1 Internal

165 1.6.1.4.2.3.1.1 Ceramic/non-slip tiles/homogenous tiles

166 1.6.1.4.2.3.1.2 Cement and sand paving

167 1.6.1.4.2.3.2 External

168 1.6.1.4.2.3.2.1 Ceramic/non-slip tiles/homogenous tiles

169 1.6.1.4.2.3.2.2 Cement and sand paving

170 1.6.1.4.2.4 Window & Door Frame

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A3

ID WBS Task Name Duration Start

171 1.6.1.4.2.5 CEILING

172 1.6.1.4.2.5.1 Asbestos free ceiling

173 1.6.1.4.2.5.2 Moisture resistence gypsum fibre ceiling

174 1.6.1.4.2.5.3 Fire risistence gypsum fibre ceiling

175 1.6.1.4.2.5.4 Fibrous plaster ceiling

176 1.6.1.4.2.5.5 Timber strip ceiling

177 1.6.1.4.2.5.6 Aluminium strip ceiling panel

178 1.6.1.4.2.5.7 Skim coats

179 1.6.1.4.2.5.8 Painting works - Emulsion paint/ varnish

180 1.6.1.4.2.6 Sanitary Fittings

181 1.6.1.4.2.7 Sundies

182 1.6.1.4.2.8 Iron Mongeries

183 1.6.1.4.3 MECHANICAL

184 1.6.1.4.3.1 Submission of Shop Drawing / Samples / Materials

185 1.6.1.4.3.2 Approval

186 1.6.1.4.3.3 Procurement

187 1.6.1.4.3.4 FAT

188 1.6.1.4.3.5 Air Conditioning

189 1.6.1.4.3.5.1 Split unit

190 1.6.1.4.3.5.1.1 Indoor

191 1.6.1.4.3.5.1.2 Out door

192 1.6.1.4.3.5.1.3 Drain water piping

193 1.6.1.4.3.5.1.4 Wiring

194 1.6.1.4.3.5.2 VRV

195 1.6.1.4.3.5.2.1 Indoor

196 1.6.1.4.3.5.2.2 Out door

197 1.6.1.4.3.5.2.3 Drain water piping

198 1.6.1.4.3.5.2.4 Wiring

199 1.6.1.4.3.5.3 Water-cooled package

200 1.6.1.4.3.5.3.1 Water Piping

201 1.6.1.4.3.5.3.2 AHU

202 1.6.1.4.3.5.3.3 Wiring

203 1.6.1.4.3.5.3.4 Ducting

204 1.6.1.4.3.5.3.5 Cooling tower

205 1.6.1.4.3.5.4 Air-cooled Package

206 1.6.1.4.3.5.4.1 Refrigerant piping

207 1.6.1.4.3.5.4.2 Ducting

208 1.6.1.4.3.5.4.3 Outdoor

209 1.6.1.4.3.5.4.4 Drain water piping

210 1.6.1.4.3.5.4.5 Indoor

211 1.6.1.4.3.5.4.6 wiring

212 1.6.1.4.3.5.5 Chiller

213 1.6.1.4.3.5.5.1 Water piping

214 1.6.1.4.3.5.5.2 Ducting

215 1.6.1.4.3.5.5.3 Wiring & Control Panel

216 1.6.1.4.3.5.5.4 AHU

217 1.6.1.4.3.5.5.5 Chiller

218 1.6.1.4.3.5.5.6 Cooling tower

219 1.6.1.4.3.6 Fire Fighting

220 1.6.1.4.3.6.1 Host reel

221 1.6.1.4.3.6.1.1 Tank

222 1.6.1.4.3.6.1.2 Hose reel drum & cabinet

223 1.6.1.4.3.6.1.3 Piping

224 1.6.1.4.3.6.1.4 Pump

225 1.6.1.4.3.6.1.5 Control

226 1.6.1.4.3.6.2 Sprinkler

227 1.6.1.4.3.6.2.1 Tank

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A4

ID WBS Task Name Duration Start

228 1.6.1.4.3.6.2.2 Piping

229 1.6.1.4.3.6.2.3 Pump

230 1.6.1.4.3.6.2.4 Sprinkler bulb

231 1.6.1.4.3.6.2.5 Control

232 1.6.1.4.3.6.3 Wet riser

233 1.6.1.4.3.6.3.1 Tank

234 1.6.1.4.3.6.3.2 Piping

235 1.6.1.4.3.6.3.3 Landing Valve & Hose cradle

236 1.6.1.4.3.6.3.4 Pump

237 1.6.1.4.3.6.3.5 Control

238 1.6.1.4.3.6.4 Fire Alarm & Detection

239 1.6.1.4.3.6.4.1 Wiring

240 1.6.1.4.3.6.4.2 Detectors & alarm bells

241 1.6.1.4.3.6.4.3 I/O Module

242 1.6.1.4.3.6.4.4 Main Fire Alarm Panel

243 1.6.1.4.3.6.5 Clean agent

244 1.6.1.4.3.6.5.1 Gas cylinder

245 1.6.1.4.3.6.5.2 Control Panel

246 1.6.1.4.3.6.5.3 Piping

247 1.6.1.4.3.7 Lif

248 1.6.1.4.3.7.1 Motor room

249 1.6.1.4.3.7.1.1 Guide rail

250 1.6.1.4.3.7.1.2 Lift car

251 1.6.1.4.3.7.1.3 Wire rope

252 1.6.1.4.3.7.1.4 Motor & controller

253 1.6.1.4.3.7.2 Motor roomless

254 1.6.1.4.3.7.2.1 Guide rail

255 1.6.1.4.3.7.2.2 Lift car

256 1.6.1.4.3.7.2.3 Wire rope

257 1.6.1.4.3.7.2.4 Motor & controller

258 1.6.1.4.3.8 Sanitary plumbing

259 1.6.1.4.3.8.1 Manhole

260 1.6.1.4.3.8.2 Underground piping for gully trap, floor trap, water closet - Ground floor

261 1.6.1.4.3.8.3 Slab floor piping for water closet, floor trap, basin - first floor & above

262 1.6.1.4.3.8.4 Pipe connection to stack, vent pipe, roof vent cowl

263 1.6.1.4.3.9 Cold water plumbing

264 1.6.1.4.3.9.1 Underground piping for incoming water supply

265 1.6.1.4.3.9.2 Hacking of wall, install cold water piping

266 1.6.1.4.3.9.3 Connection of riser pipe from ground to roof tank

267 1.6.1.4.3.9.4 Connection of dropper pipe from roof tank to pipe inside wall

268 1.6.1.4.4 ELECTRICAL

269 1.6.1.4.4.1 Submission of Shop Drawing / Samples / Materials

270 1.6.1.4.4.2 Approval

271 1.6.1.4.4.3 Procurement

272 1.6.1.4.4.4 FAT

273 1.6.1.4.4.5 High Voltage System

274 1.6.1.4.4.5.1 Installation HT Equipment

275 1.6.1.4.4.5.2 Testing and Commissioning

276 1.6.1.4.4.6 Low Voltage System

277 1.6.1.4.4.6.1 Internal LV Installation

278 1.6.1.4.4.6.1.1 Installation of Conduits in Slab

279 1.6.1.4.4.6.1.2 Installation of Conduits in Wall

280 1.6.1.4.4.6.1.3 Pull Wire In Conduits

281 1.6.1.4.4.6.1.4 Installation of Switches, SSO and Fittings

282 1.6.1.4.4.6.1.5 Installation of Distribution Boards

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A5

ID WBS Task Name Duration Start

283 1.6.1.4.4.6.2 Lightning Protection System

284 1.6.1.4.4.6.3 Uninterruptible Power Supply System

285 1.6.1.4.4.6.4 Telephone Services (Internal & External)

286 1.6.1.4.4.6.5 Generator Set

287 1.6.1.4.4.6.6 Cable Trench

288 1.6.1.4.4.6.7 Sewerage Treatment Plant

289 1.6.1.4.4.7 Extra Low Voltage System

290 1.6.1.4.4.7.1 ELV Wiring Public Address Systems/Fireman Emergency Announcement

291 1.6.1.4.4.7.2 Public Address Systems/Fireman Emergency Announcement

292 1.6.1.4.4.7.3 Conference Equipment and Teleconferencing Facilities

293 1.6.1.4.4.7.4 Audio-Visual Equipment

294 1.6.1.4.4.7.5 Sound Reinforcement System

295 1.6.1.4.4.7.6 Stage Lighting System

296 1.6.1.4.4.7.7 Stage Curtain System

297 1.6.1.4.4.7.8 Master TV/FM Antennae System and Equipment

298 1.6.1.4.4.7.9 Security System

299 1.6.1.4.4.7.10 Queue System

300 1.6.1.4.4.7.11 Master Clock System

301 1.6.1.4.4.7.12 Electronic Display Board System

302 1.6.1.4.4.7.13 Electronic Info Kiosk

303 1.6.1.4.4.7.14 Intergrated Building Management System

304 1.6.1.4.4.8 Information & Communication Technology

305 1.6.1.4.4.8.1 Structured Cabling System

306 1.6.1.4.4.8.2 Network System

307 1.6.1.4.4.8.3 Voice System

308 1.6.1.4.4.8.4 Testing and Commissioning

309 1.6.1.4.4.9 External Infrastructure Works

310 1.6.1.4.4.9.1 High Voltage Installation

311 1.6.1.4.4.9.2 Telephone Infrastructure

312 1.6.1.4.4.9.3 Road/Street/Compound Lighting

313 1.6.1.4.5 Pre Testing

314 1.6.1.4.6 As-Built

315 1.6.1.4.7 Completion of Ground Floor

316 1.6.1.5 FIRST FLOOR

317 1.6.1.5.1 SUPER STRUCTURE

318 1.6.1.5.1.1 First Floor Beam

319 1.6.1.5.1.2 First Floor Slab

320 1.6.1.5.1.3 First Floor Column

321 1.6.1.5.2 ARCHITECT

322 1.6.1.5.2.1 WALLS

323 1.6.1.5.2.1.1 EXTERNAL WALL

324 1.6.1.5.2.1.1.1 Brickwall / RC Wall

325 1.6.1.5.2.1.1.2 Prepare and apply damp proof course

326 1.6.1.5.2.1.1.3 Coping

327 1.6.1.5.2.1.1.4 Plastering

328 1.6.1.5.2.1.1.5 Finishes

329 1.6.1.5.2.1.1.5.1 Tiles

330 1.6.1.5.2.1.1.5.2 Paint

331 1.6.1.5.2.1.2 INTERNAL WALL

332 1.6.1.5.2.1.2.1 Brickwall / RC Wall

333 1.6.1.5.2.1.2.2 Prepare and apply damp proof course

334 1.6.1.5.2.1.2.3 Partition

335 1.6.1.5.2.1.2.4 Feature Wall

336 1.6.1.5.2.1.2.5 Plastering

337 1.6.1.5.2.1.2.6 Finishes

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A6

ID WBS Task Name Duration Start

338 1.6.1.5.2.1.2.6.1 Tiles

339 1.6.1.5.2.1.2.6.2 Paint

340 1.6.1.5.2.2 Door & Window Frame

341 1.6.1.5.2.3 FLOOR

342 1.6.1.5.2.3.1 Internal

343 1.6.1.5.2.3.1.1 Ceramic/non-slip tiles/homogenous tiles

344 1.6.1.5.2.3.1.2 Cement and sand paving

345 1.6.1.5.2.3.2 External

346 1.6.1.5.2.3.2.1 Ceramic/non-slip tiles/homogenous tiles

347 1.6.1.5.2.3.2.2 Cement and sand paving

348 1.6.1.5.2.4 Window & Door Frame

349 1.6.1.5.2.5 CEILING

350 1.6.1.5.2.5.1 Asbestos free ceiling

351 1.6.1.5.2.5.2 Moisture resistence gypsum fibre ceiling

352 1.6.1.5.2.5.3 Fire risistence gypsum fibre ceiling

353 1.6.1.5.2.5.4 Fibrous plaster ceiling

354 1.6.1.5.2.5.5 Timber strip ceiling

355 1.6.1.5.2.5.6 Aluminium strip ceiling panel

356 1.6.1.5.2.5.7 Skim coats

357 1.6.1.5.2.5.8 Painting works - Emulsion paint/ varnish

358 1.6.1.5.2.6 Sanitary Fittings

359 1.6.1.5.2.7 Sundies

360 1.6.1.5.2.8 Iron Mongeries

361 1.6.1.5.3 STAIRCASE

362 1.6.1.5.3.1 Structure Works

363 1.6.1.5.3.2 Handrail

364 1.6.1.5.3.2.1 Horizontal or Raking handrail

365 1.6.1.5.3.2.2 Balustrade

366 1.6.1.5.3.2.3 Intermediate Rail

367 1.6.1.5.3.3 Finishes

368 1.6.1.5.3.3.1 Cement and sand paving

369 1.6.1.5.3.3.2 Tiles/carpet/timber flooring

370 1.6.1.5.3.4 Painting

371 1.6.1.5.3.4.1 Emulsion paint/ Acrylic Paint

372 1.6.1.5.3.4.2 Varnish on woodwork surfaces

373 1.6.1.5.3.4.3 Mordant solution, metallic primer & gloss enamel paint

374 1.6.1.5.4 MECHANICAL

375 1.6.1.5.4.1 Air Conditioning

376 1.6.1.5.4.1.1 Split unit

377 1.6.1.5.4.1.1.1 Indoor

378 1.6.1.5.4.1.1.2 Out door

379 1.6.1.5.4.1.1.3 Drain water piping

380 1.6.1.5.4.1.1.4 Wiring

381 1.6.1.5.4.1.2 VRV

382 1.6.1.5.4.1.2.1 Indoor

383 1.6.1.5.4.1.2.2 Out door

384 1.6.1.5.4.1.2.3 Drain water piping

385 1.6.1.5.4.1.2.4 Wiring

386 1.6.1.5.4.1.3 Water-cooled package

387 1.6.1.5.4.1.3.1 Water Piping

388 1.6.1.5.4.1.3.2 AHU

389 1.6.1.5.4.1.3.3 Wiring

390 1.6.1.5.4.1.3.4 Ducting

391 1.6.1.5.4.1.3.5 Cooling tower

392 1.6.1.5.4.1.4 Air-cooled Package

393 1.6.1.5.4.1.4.1 Refrigerant piping

394 1.6.1.5.4.1.4.2 Ducting

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A7

ID WBS Task Name Duration Start

395 1.6.1.5.4.1.4.3 Outdoor

396 1.6.1.5.4.1.4.4 Drain water piping

397 1.6.1.5.4.1.4.5 Indoor

398 1.6.1.5.4.1.4.6 wiring

399 1.6.1.5.4.1.5 Chiller

400 1.6.1.5.4.1.5.1 Water piping

401 1.6.1.5.4.1.5.2 Ducting

402 1.6.1.5.4.1.5.3 Wiring & Control Panel

403 1.6.1.5.4.1.5.4 AHU

404 1.6.1.5.4.1.5.5 Chiller

405 1.6.1.5.4.1.5.6 Cooling tower

406 1.6.1.5.4.2 Fire Fighting

407 1.6.1.5.4.2.1 Host reel

408 1.6.1.5.4.2.1.1 Tank

409 1.6.1.5.4.2.1.2 Hose reel drum & cabinet

410 1.6.1.5.4.2.1.3 Piping

411 1.6.1.5.4.2.1.4 Pump

412 1.6.1.5.4.2.1.5 Control

413 1.6.1.5.4.2.2 Sprinkler

414 1.6.1.5.4.2.2.1 Tank

415 1.6.1.5.4.2.2.2 Piping

416 1.6.1.5.4.2.2.3 Pump

417 1.6.1.5.4.2.2.4 Sprinkler bulb

418 1.6.1.5.4.2.2.5 Control

419 1.6.1.5.4.2.3 Wet riser

420 1.6.1.5.4.2.3.1 Tank

421 1.6.1.5.4.2.3.2 Piping

422 1.6.1.5.4.2.3.3 Landing Valve & Hose cradle

423 1.6.1.5.4.2.3.4 Pump

424 1.6.1.5.4.2.3.5 Control

425 1.6.1.5.4.2.4 Fire Alarm & Detection

426 1.6.1.5.4.2.4.1 Wiring

427 1.6.1.5.4.2.4.2 Detectors & alarm bells

428 1.6.1.5.4.2.4.3 I/O Module

429 1.6.1.5.4.2.4.4 Main Fire Alarm Panel

430 1.6.1.5.4.2.5 Clean agent

431 1.6.1.5.4.2.5.1 Gas cylinder

432 1.6.1.5.4.2.5.2 Control Panel

433 1.6.1.5.4.2.5.3 Piping

434 1.6.1.5.4.3 Lif

435 1.6.1.5.4.3.1 Motor room

436 1.6.1.5.4.3.1.1 Guide rail

437 1.6.1.5.4.3.1.2 Lift car

438 1.6.1.5.4.3.1.3 Wire rope

439 1.6.1.5.4.3.1.4 Motor & controller

440 1.6.1.5.4.3.2 Motor roomless

441 1.6.1.5.4.3.2.1 Guide rail

442 1.6.1.5.4.3.2.2 Lift car

443 1.6.1.5.4.3.2.3 Wire rope

444 1.6.1.5.4.3.2.4 Motor & controller

445 1.6.1.5.4.4 Sanitary plumbing

446 1.6.1.5.4.4.1 Manhole

447 1.6.1.5.4.4.2 Underground piping for gully trap, floor trap, water closet - Ground floor

448 1.6.1.5.4.4.3 Slab floor piping for water closet, floor trap, basin - first floor & above

449 1.6.1.5.4.4.4 Pipe connection to stack, vent pipe, roof vent cowl

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A8

ID WBS Task Name Duration Start

450 1.6.1.5.4.5 Cold water plumbing

451 1.6.1.5.4.5.1 Underground piping for incoming water supply

452 1.6.1.5.4.5.2 Hacking of wall, install cold water piping

453 1.6.1.5.4.5.3 Connection of riser pipe from ground to roof tank

454 1.6.1.5.4.5.4 Connection of dropper pipe from roof tank to pipe inside wall

455 1.6.1.5.5 ELECTRICAL

456 1.6.1.5.5.1 High Voltage System

457 1.6.1.5.5.1.1 Installation HT Equipment

458 1.6.1.5.5.1.2 Testing and Commissioning

459 1.6.1.5.5.2 Low Voltage System

460 1.6.1.5.5.2.1 Internal LV Installation

461 1.6.1.5.5.2.1.1 Installation of Conduits in Slab

462 1.6.1.5.5.2.1.2 Installation of Conduits in Wall

463 1.6.1.5.5.2.1.3 Pull Wire In Conduits

464 1.6.1.5.5.2.1.4 Installation of Switches, SSO and Fittings

465 1.6.1.5.5.2.1.5 Installation of Distribution Boards

466 1.6.1.5.5.2.2 Lightning Protection System

467 1.6.1.5.5.2.3 Uninterruptible Power Supply System

468 1.6.1.5.5.2.4 Telephone Services (Internal & External)

469 1.6.1.5.5.2.5 Generator Set

470 1.6.1.5.5.2.6 Cable Trench

471 1.6.1.5.5.2.7 Sewerage Treatment Plant

472 1.6.1.5.5.3 Extra Low Voltage System

473 1.6.1.5.5.3.1 ELV Wiring Public Address Systems/Fireman Emergency Announcement

474 1.6.1.5.5.3.2 Public Address Systems/Fireman Emergency Announcement

475 1.6.1.5.5.3.3 Conference Equipment and Teleconferencing Facilities

476 1.6.1.5.5.3.4 Audio-Visual Equipment

477 1.6.1.5.5.3.5 Sound Reinforcement System

478 1.6.1.5.5.3.6 Stage Lighting System

479 1.6.1.5.5.3.7 Stage Curtain System

480 1.6.1.5.5.3.8 Master TV/FM Antennae System and Equipment

481 1.6.1.5.5.3.9 Security System

482 1.6.1.5.5.3.10 Queue System

483 1.6.1.5.5.3.11 Master Clock System

484 1.6.1.5.5.3.12 Electronic Display Board System

485 1.6.1.5.5.3.13 Electronic Info Kiosk

486 1.6.1.5.5.3.14 Intergrated Building Management System

487 1.6.1.5.5.4 Information & Communication Technology

488 1.6.1.5.5.4.1 Structured Cabling System

489 1.6.1.5.5.4.2 Network System

490 1.6.1.5.5.4.3 Voice System

491 1.6.1.5.5.4.4 Testing and Commissioning

492 1.6.1.5.5.5 External Infrastructure Works

493 1.6.1.5.5.5.1 High Voltage Installation

494 1.6.1.5.5.5.2 Telephone Infrastructure

495 1.6.1.5.5.5.3 Road/Street/Compound Lighting

496 1.6.1.5.6 Pre Testing

497 1.6.1.5.7 As-Built

498 1.6.1.5.8 Completion of First Floor

499 1.6.1.6 ROOF FLOOR

500 1.6.1.6.1 Roof Floor Beam

501 1.6.1.6.2 Roof Floor Slab

502 1.6.1.6.3 Waterproofing

503 1.6.1.6.4 Ponding Test

504 1.6.1.6.5 Floor Screed

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A9

ID WBS Task Name Duration Start

505 1.6.1.6.6 Roof truss, purlin

506 1.6.1.6.7 Roof Sisalation

507 1.6.1.6.8 Roof Insulation

508 1.6.1.6.9 Roofing sheet/metal deck / tile

509 1.6.1.6.10 Rainwater Drainage & Gutter

510 1.6.1.6.11 As-Built

511 1.6.1.6.12 Completion of Roof Floor

512 1.6.2 Blok B

513 1.6.3 Blok C

514 1.6.4 Ancillary Building

515 1.6.4.1 Pump House

516 1.6.4.2 Guard House

517 1.6.4.3 TNB Sub-Station

518 1.6.4.4 Rubbish Compartment

519 1.6.4.5 Gazebo

520 1.7 RETAINING STRUCTURES

521 1.7.1 R.C Wall

522 1.7.2 Rubber Wall

523 1.7.3 Crib Wall

524 1.7.4 Gabion

525 1.8 EXTERNAL WORKS

526 1.8.1 SURFACE DRAINAGE

527 1.8.1.1 300mm - 600mm dia. Precast Concrete Block Drain

528 1.8.1.1.1 Setting out

529 1.8.1.1.2 Excavation & base

530 1.8.1.1.3 Laying p.c drain

531 1.8.1.1.4 Caping beam

532 1.8.1.1.5 Slab cover

533 1.8.1.2 BRICK SUMP

534 1.8.1.2.1 Brick Sump Size 1200mm x 1200mm

535 1.8.1.2.2 Brick Sump Size 900mm x 900mm

536 1.8.1.2.3 Brick Sump Size 1050mm x 1050mm

537 1.8.1.3 BOX CULVERT

538 1.8.1.3.1 Box culvert size 600mm x 900mm

539 1.8.1.3.2 Box culvert 600mm x 600mm

540 1.8.1.4 PRECAST ONCRETE PIPE CULVERT

541 1.8.1.4.1 600MM Dia. Precast Concrete Class 'S' Pipe Culvert

542 1.8.1.4.2 750MM Dia. Precast Concrete Class 'S' Pipe Culvert

543 1.8.2 SEWERAGE SYSTEM

544 1.8.2.1 Excavate trench

545 1.8.2.2 Pipe Installation

546 1.8.2.2.1 Bedding

547 1.8.2.2.2 Lay Pipe

548 1.8.2.3 Precast Reinforced Concrete Manhole

549 1.8.2.3.1 Normal type

550 1.8.2.3.2 Drop Type

551 1.8.2.4 Sewerage Treatment Plant

552 1.8.2.4.1 Excavation and base

553 1.8.2.4.2 Installation tank

554 1.8.2.4.3 Connection internal piping

555 1.8.2.4.4 Back fill with sand

556 1.8.2.4.5 Pump house & sludge tank

557 1.8.2.4.6 M & E works

558 1.8.2.4.7 Fencing

559 1.8.2.4.8 Premix works

560 1.8.2.4.9 Install discharging manhole

561 1.8.2.4.10 Testing & Commissioning

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A10

ID WBS Task Name Duration Start

562 1.8.3 WATER INFRASTRUCTURE

563 1.8.3.1 Water Reticulation

564 1.8.3.1.1 Excavate pipe trenching

565 1.8.3.1.2 Supply, Lay & Test piping

566 1.8.3.1.2.1 Thrust Block

567 1.8.3.1.2.2 Mild steel pipe for Culvert or Drain Crossing

568 1.8.3.1.2.3 Precast concrete

569 1.8.3.1.2.4 Sluice valve chamber

570 1.8.3.1.2.5 Hydrant indicator post

571 1.8.3.1.2.6 Sluice valve indicator post

572 1.8.3.1.2.7 Valve

573 1.8.3.1.2.8 Fire hydrant

574 1.8.3.1.2.9 Tapping to main supply pipe

575 1.8.3.1.2.10 Termination of existing pipe

576 1.8.3.1.2.11 Flushing & Disinfecting the tested pipeline with chlorine

577 1.8.3.2 Suction Tank

578 1.8.3.3 Elevated Water Tank/ Reservoir

579 1.9 ROAD, HARSTANDING AND FOOTPATH

580 1.9.1 Road and Carparks

581 1.9.1.1 Excavation to reduce level

582 1.9.1.2 Sub-base

583 1.9.1.3 Base course

584 1.9.1.4 Binder course

585 1.9.1.5 Wearing course

586 1.9.2 Concrete Hardstanding

587 1.9.2.1 Excavation to reduce level

588 1.9.2.2 Crusher run

589 1.9.2.3 Sand or other approved material

590 1.9.2.4 Concrete hardstanding including heavy duty, coloured & pattern

591 1.9.2.5 Interlocking Pavers

592 1.9.3 Excavation to reduce level

593 1.9.3.1 Crusher run

594 1.9.3.2 Sand or other approved material

595 1.9.3.3 Interlocking pavers

596 1.9.3.4 Concrete edge restrain

597 1.10 COVERED WAY

598 1.10.1 Covered Way 2.1m High

599 1.10.2 Covered Way 5.7m High

600 1.11 FENCING & GATE

601 1.11.1 Chain Link Fence

602 1.11.2 Decorative Fence

603 1.11.3 Security Fence

604 1.11.4 Gate

605 1.11.5 Painting

606 1.11.6 FLAG POST

607 1.12 TURFING AND LANDSCAPING

608 1.12.1 Turfing

609 1.12.1.1 Trim, level and grade gorund

610 1.12.1.2 Close turfing to slope

611 1.12.1.3 Close turfing to platform level

612 1.12.1.4 Sport turfing to platform level

613 1.12.2 Landscaping

614 1.12.2.1 Hardscape

615 1.12.2.2 Softscape

616 1.13 FURNITURE

617 1.13.1 Fixed Furniture

618 1.13.2 Loose Furniture

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A11

ID WBS Task Name Duration Start

619 1.13.3 Interior Design

620 1.13.3.1 Fixed Furniture

621 1.13.3.2 Loose Furniture

622 1.14 Signages

623 1.15 Testing And Commissioning

624 1.16 Compilation of As-Built

625 1.17 Clearing, Cleaning And Making Good On Completion

626 1.18 Handing Over

TEMPLAT WBS BAGI PROJEK BANGUNAN (2018)

Unit Amalan Terbaik, CPAB | Page A12

APPENDIKS B

Templat WBS Bagi Projek Jalan

ID WBS Task Name Duration Start

1 1 PROJECT - ROADWOKS

2 1.1 SITE POSSESSION

3 1.2 PRELIMINARIES

4 1.2.1 Performance Bond

5 1.2.2 Insurance of Works

6 1.2.3 Project Signboard

7 1.2.4 Site Site Survey & Setting Out

8 1.2.5 Work Program

9 1.2.6 Temporary Diversion and Relocation of Existing Overhead And Underground Services

10 1.2.7 Construction Plan

11 1.2.8 Contractor's Plant

12 1.2.9 Temporary Water and Power Supplies For The Works

13 1.2.10 Site Security

14 1.2.11 Temporary Access And Maintenance Of Existing Roads

15 1.2.12 Control of Workmen, Plant And Machinery At Site

16 1.2.13 Contractor's Temporary Accomadation And Facilities For Workmen Living On Site

17 1.2.14 Contractor's Office And Storage

18 1.2.15 Care And Protection Of Materials And Works

19 1.2.16 Progress Photographs

20 1.2.17 Material Testing Laboratory And Staff

21 1.2.18 Office Accomadation For SO

22 1.2.19 Telephone For SO

23 1.2.20 Survey Instruments And Personnel

24 1.2.21 Site Items For SO / Office Equipments And Facilities

25 1.2.22 Safe Working Area

26 1.2.23 Safety, Health And Welfare

27 1.2.24 Keeping The Site Tidy

28 1.2.25 Coordination Of Mechanical And Electrical ( M & E) Services

29 1.2.26 Site Agents And Assistants

30 1.3 TRAFFIC MANAGEMENT AND CONTROL

31 1.3.1 Temp Road Furniture

32 1.3.1.1 Installation temp road furniture

33 1.3.1.1.1 Precast Movabale RC Barriers

34 1.3.1.1.2 Lightweight Movabale Barriers

35 1.3.1.1.3 Lightweight traffic guidance cone

36 1.3.1.1.4 Lightweight Movabale Barriers with delineators

37 1.3.1.1.5 Blinkes with batteries

38 1.3.1.1.6 Double sided reflective strings delineators

39 1.3.1.1.7 Flashing arrow

40 1.3.1.1.8 Sand Bag

41 1.3.1.1.9 Temporary lighting

42 1.3.1.2 Removal of temporary furniture

43 1.3.1.3 Maintenance of temporary furniture

44 1.3.2 Temporary Guardrail

45 1.3.3 Temporary Sign

46 1.3.3.1 Installation

47 1.3.3.2 Maintenance

48 1.3.4 Temporary Road Diversion

49 1.3.4.1 Earthworks

50 1.3.4.2 Pavement

51 1.3.4.3 Removal of temporary road diversion & structures

52 1.3.5 Road Marking

53 1.3.5.1 Installation

54 1.3.5.2 Removal

55 1.3.6 Traffic Management Plan & Report

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B1

ID WBS Task Name Duration Start

56 1.3.6.1 Traffic Management Plan

57 1.3.6.2 Traffic Safety Plan

58 1.3.6.2.1 Traffic Safety Plan 1

59 1.3.6.2.2 Traffic Safety Plan 2

60 1.3.6.2.3 Traffic Safety Plan 3

61 1.3.6.2.4 Traffic Safety Plan 4

62 1.3.6.2.5 Traffic Safety Plan 5

63 1.3.6.2.6 Traffic Safety Plan 6

64 1.4 ENVIRONMENTAL PROTECTION WORKS

65 1.4.1 Non- Physical Work

66 1.4.1.1 EIA

67 1.4.1.1.1 EIA Report

68 1.4.1.1.2 Supplementary EIA Report

69 1.4.1.2 EMP

70 1.4.1.2.1 Prepare & Execute EMP

71 1.4.1.2.2 Provide Full Time EO

72 1.4.1.2.3 Wild Life Mgt Plan

73 1.4.1.2.4 Flora Survey

74 1.4.1.2.5 Prepare Erosion Sediment Control Plan

75 1.4.1.2.6 Update & Revise EMP

76 1.4.1.3 Monitoring Auditing & Training

77 1.4.1.3.1 Monitoring Report

78 1.4.1.3.2 Environmental Audit

79 1.4.1.3.3 Training

80 1.4.1.3.4 Air Quality Monitoring

81 1.4.1.3.5 Noise Monitoring

82 1.4.1.3.6 Water Quality Monitoring

83 1.4.2 Physical Work

84 1.4.2.1 Dust & Mud Control

85 1.4.2.1.1 Water Browser Truck

86 1.4.2.1.2 Tyre Washing Facilities

87 1.4.2.1.3 Wash Trough

88 1.4.2.1.4 Water Sprinkler

89 1.4.2.2 Sediment Control

90 1.4.2.2.1 Silt Fence

91 1.4.2.2.2 Silt Trap & Sediment Basin

92 1.4.2.2.3 Gabion Wall

93 1.4.2.2.4 Check Dam

94 1.4.2.3 Silt Curtain

95 1.4.2.4 Topsoil Protection

96 1.4.2.4.1 Plastic Sheeting for turfing & Landscaping

97 1.4.2.4.2 Siltration Control

98 1.4.2.5 Fuel Spillage Management

99 1.4.2.5.1 Containment Bund for Bulk Fuel Tank

100 1.4.2.6 Waste Management

101 1.4.2.6.1 Scheduled Waste Disposal

102 1.4.2.6.2 Grease Trap

103 1.4.2.7 Management of Disposal Site

104 1.4.2.7.1 Eatrh Works

105 1.4.2.7.2 Drainage

106 1.4.2.7.3 Retaining Wall

107 1.4.2.8 Noise Control

108 1.4.2.8.1 Noise Barrier

109 1.4.2.9 Flora Management

110 1.4.2.10 Wild Life management

111 1.5 ROUTINE MAINTENANCE WORKS

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B2

ID WBS Task Name Duration Start

112 1.5.1 MAINTAIN EXISTING ROAD

113 1.5.2 ROAD FURNITURES

114 1.5.3 BRIDGES & CULVERTS

115 1.5.4 ROADLINE MARIKINGS

116 1.5.5 DRAINAGE

117 1.5.6 Landscaping

118 1.6 ROADWORKS

119 1.6.1 Land Aquasition

120 1.6.2 Relocation of Uilities

121 1.6.3 Chainage 0.00 - 0.00

122 1.6.3.1 Site Clearance and Demolition Works

123 1.6.3.1.1 Site Clearance

124 1.6.3.1.1.1 Upgrading of existing road

125 1.6.3.1.1.1.1 General site clearance

126 1.6.3.1.1.2 Construction of new road

127 1.6.3.1.1.2.1 Bushes

128 1.6.3.1.1.2.2 Paddy Plantation

129 1.6.3.1.1.2.3 Swampy Land

130 1.6.3.1.1.2.4 Plantation

131 1.6.3.1.1.2.5 Forest Reserve

132 1.6.3.1.1.2.6 Others

133 1.6.3.1.2 Demolition Works

134 1.6.3.1.2.1 Building

135 1.6.3.1.2.1.1 Brickwork buildings

136 1.6.3.1.2.1.1.1 Single storey

137 1.6.3.1.2.1.1.2 Double storey

138 1.6.3.1.2.1.1.3 Others

139 1.6.3.1.2.1.2 Concrete buildings

140 1.6.3.1.2.1.2.1 Single storey

141 1.6.3.1.2.1.2.2 Double storey

142 1.6.3.1.2.1.2.3 Others

143 1.6.3.1.2.1.3 Mansonry buildings

144 1.6.3.1.2.1.3.1 Single storey

145 1.6.3.1.2.1.3.2 Double storey

146 1.6.3.1.2.1.3.3 Others

147 1.6.3.1.2.1.4 Steel buildings

148 1.6.3.1.2.1.4.1 Single storey

149 1.6.3.1.2.1.4.2 Double storey

150 1.6.3.1.2.1.4.3 Others

151 1.6.3.1.2.1.5 Timber buildings

152 1.6.3.1.2.1.5.1 Single storey

153 1.6.3.1.2.1.5.2 Double storey

154 1.6.3.1.2.1.5.3 Others

155 1.6.3.1.2.2 Other Structures

156 1.6.3.1.2.2.1 Fences and Gates

157 1.6.3.1.2.2.2 Bridges

158 1.6.3.1.2.2.3 Culvert

159 1.6.3.1.2.2.4 Pipe Culvert

160 1.6.3.1.2.2.5 Box Culvert

161 1.6.3.1.2.2.6 Drain

162 1.6.3.1.2.2.7 Guard rails

163 1.6.3.1.2.2.8 sump

164 1.6.3.1.2.2.9 Retaining wall

165 1.6.3.1.2.2.10 Inlet/outlet structures

166 1.6.3.1.2.2.11 others

167 1.6.3.1.3 Dismantle & Send to Store

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B3

ID WBS Task Name Duration Start

168 1.6.3.1.3.1 Fences and gates

169 1.6.3.1.3.2 Sign Board

170 1.6.3.1.3.3 Guard rail

171 1.6.3.2 Earthworks

172 1.1 Stripping Top Soil

173 1.1.1 Stripping & Disposal

174 1.1.2 Stripping & Reuse

175 1.2 Excavation & Disposal

176 1.2.1 Common cutting

177 1.2.1.1 Excavate & form embankment

178 1.2.1.2 Excavate & dispose

179 1.2.2 Hard Material

180 1.2.2.1 Excavate & Form embankment

181 1.2.2.2 Excavate & dispose

182 1.2.3 Rock

183 1.2.3.1 Open blasting

184 1.2.3.1.1 Excavate & form embankment

185 1.2.3.1.2 Excavate & disposal

186 1.2.3.2 Control blasting

187 1.2.3.2.1 Excavate & form embankment

188 1.2.3.2.2 Excavate & disposal

189 1.2.3.3 Ripper unit

190 1.2.3.3.1 Excavate & form embankment

191 1.2.3.3.2 Excavate & disposal

192 1.2.3.4 Preumatic unit

193 1.2.3.4.1 Excavate & form embankment

194 1.2.3.4.2 Excavate & disposal

195 1.2.4 Excavate & disposal unsuitable material

196 1.3 Form embankment; spread, grade & compact

197 1.3.1 suitable material

198 1.3.2 imported material

199 1.3.3 hard material

200 1.3.4 rock material

201 1.3.5 imported rock material

202 1.4 Turfing & hydroseeding

203 1.4.1 close turfing

204 1.4.2 hydroseeding

205 1.4.3 hydroseeding with fibromat

206 1.4.4 vertiver grass

207 1.5 Field Density Test

208 1.6.3.3 Geotechnical Works

209 1.6.3.3.1 Soft Ground Improvement

210 1.6.3.3.1.1 Soft Ground Replacement/ Stability

211 1.6.3.3.1.1.1 Lay Geotextile

212 1.6.3.3.1.1.1.1 Non-woven

213 1.6.3.3.1.1.1.2 Woven

214 1.6.3.3.1.1.2 Placement and Compaction

215 1.6.3.3.1.1.2.1 River/ mining Sand

216 1.6.3.3.1.1.2.2 Excavated Suitable Material

217 1.6.3.3.1.1.2.3 Imported Earth

218 1.6.3.3.1.2 Prefabricated Vertical Drains

219 1.6.3.3.1.2.1 Mobilization

220 1.6.3.3.1.2.2 Lay Geotextile

221 1.6.3.3.1.2.2.1 Non-woven

222 1.6.3.3.1.2.2.2 Woven

223 1.6.3.3.1.2.3 Drainage Blanket

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B4

ID WBS Task Name Duration Start

224 1.6.3.3.1.2.4 Verttical Drain

225 1.6.3.3.1.2.5 Placement and Compaction of river/mining sand

226 1.6.3.3.1.2.6 Demobilazation

227 1.6.3.3.1.3 Stone Columns/ Geopiers/ Soil Cement Columns/ Chemical Columns/ Sand Columns

228 1.6.3.3.1.3.1 Mobilization and Demobilazation

229 1.6.3.3.1.3.1.1 Mobilization

230 1.6.3.3.1.3.2 Lay Geotextile

231 1.6.3.3.1.3.2.1 Non-woven

232 1.6.3.3.1.3.2.2 Woven

233 1.6.3.3.1.3.3 Stone Columns/ Geopiers/ Soil Cement Columns/ Chemical Columns/ Sand Columns

234 1.6.3.3.1.3.4 Drainage Blanket

235 1.6.3.3.1.3.5 Placement and Compaction of river/mining sand

236 1.6.3.3.1.3.6 Demobilization

237 1.6.3.3.1.3.7 Test Load

238 1.6.3.3.1.3.7.1 Maximum test load

239 1.6.3.3.1.3.7.2 Group columns

240 1.6.3.3.1.4 Surcharge

241 1.6.3.3.1.4.1 Excavated suitable fill materials

242 1.6.3.3.1.4.2 Imported fill materials

243 1.6.3.3.1.4.3 Surcharge

244 1.6.3.3.1.4.4 Removal of surplus surcharge

245 1.6.3.3.1.5 Piled Embankment

246 1.6.3.3.1.5.1 RC Pile

247 1.6.3.3.1.5.1.1 Survey

248 1.6.3.3.1.5.1.2 Mobilise

249 1.6.3.3.1.5.1.3 Test pile

250 1.6.3.3.1.5.1.4 Load Test

251 1.6.3.3.1.5.1.4.1 Maintained Load Test

252 1.6.3.3.1.5.1.4.2 PDA

253 1.6.3.3.1.5.1.5 Working Pile

254 1.6.3.3.1.5.1.6 Cutting off pile head

255 1.6.3.3.1.5.1.7 Concreting works

256 1.6.3.3.1.5.1.8 As- Built

257 1.6.3.3.1.5.1.9 Demobilise

258 1.6.3.3.1.5.2 RC Slab

259 1.6.3.3.1.5.2.1 Excavate material

260 1.6.3.3.1.5.2.2 Fill up material to O.G.L

261 1.6.3.3.1.5.2.3 Concreting Works

262 1.6.3.3.2 Instrumentation

263 1.6.3.3.2.1 Supply and Install

264 1.6.3.3.2.1.1 Surface settlement marker

265 1.6.3.3.2.1.2 Settlement Gauge

266 1.6.3.3.2.1.3 Piezometers

267 1.6.3.3.2.1.4 Inclinometers

268 1.6.3.3.2.2 Install deep levelling datum penetrating

269 1.6.3.3.2.3 Monitoring & Analysing

270 1.6.3.3.2.4 Monthly Report

271 1.6.3.3.3 Slope Stabilization Works

272 1.6.3.3.3.1 Soil Nailing

273 1.6.3.3.3.1.1 Drilling & Grouting

274 1.6.3.3.3.1.2 Pull out Test on the soil nails

275 1.6.3.3.3.1.3 Proof test

276 1.6.3.3.3.1.4 Horizontal Drains

277 1.6.3.3.3.1.5 Concrete on Slope

278 1.6.3.3.3.2 Rock Bolt

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B5

ID WBS Task Name Duration Start

279 1.6.3.3.3.2.1 Drilling & Grouting

280 1.6.3.3.3.2.2 Installation of rock bolt

281 1.6.3.3.3.2.3 Concrete on unstable fractured rock

282 1.6.3.3.3.2.4 Pull Out Test

283 1.6.3.3.3.3 Ground Anchorage

284 1.6.3.3.3.3.1 Drilling & Grouting

285 1.6.3.3.3.3.2 Supply & Install

286 1.6.3.3.3.3.3 Pull Out Test

287 1.6.3.3.3.4 Horizontal Drains

288 1.6.3.3.4 Retaining System

289 1.6.3.3.4.1 Reinforced Soil Walls

290 1.6.3.3.4.1.1 Reinforced Soil Wall Components

291 1.6.3.3.4.1.2 Precast Concrete Panels

292 1.6.3.3.4.1.3 Cast In-situ Mass Concrete

293 1.6.3.3.4.1.4 Drainage Blanket

294 1.6.3.3.4.1.5 Fill River/mining Sand

295 1.6.3.3.4.2 Reinforced Soil Slopes

296 1.6.3.3.4.2.1 Geogrid

297 1.6.3.3.4.2.1.1 Reinforced walls or slopes

298 1.6.3.3.4.2.1.2 Stabilise embankment toe

299 1.6.3.3.4.3 Reinforced Concrete Retaining Walls

300 1.6.3.3.4.3.1 Excavation

301 1.6.3.3.4.3.2 UPVC pipes

302 1.6.3.3.4.3.3 Free Draining Material

303 1.6.3.3.4.3.4 Joint

304 1.6.3.3.4.3.4.1 Construction Joint

305 1.6.3.3.4.3.4.2 Expansion Joint

306 1.6.3.3.4.3.4.3 Sealer

307 1.6.3.3.4.3.5 Steel Reinforcement

308 1.6.3.3.4.3.6 Lay Bituminous Coating

309 1.6.3.4 Drainage works

310 1.6.3.4.1 Temporary work

311 1.6.3.4.2 New pipe culvert

312 1.6.3.4.2.1 Earthworks

313 1.6.3.4.2.2 Foundation

314 1.6.3.4.2.3 Pipe culvert

315 1.6.3.4.2.4 Inlet/ outlet structures

316 1.6.3.4.2.5 Fill material

317 1.6.3.4.3 Extension of existing pipe culvert

318 1.6.3.4.3.1 Demolition & hacking

319 1.6.3.4.3.2 Earthworks

320 1.6.3.4.3.3 Foundation

321 1.6.3.4.3.4 Pipe culvert

322 1.6.3.4.3.5 Inlet/ Outlet structures

323 1.6.3.4.3.6 Fill material

324 1.6.3.4.4 New precast box culvert < 3.0m

325 1.6.3.4.4.1 Earthworks

326 1.6.3.4.4.2 Foundation

327 1.6.3.4.4.3 Precast box culvert

328 1.6.3.4.4.4 Inlet/ Outlet structures

329 1.6.3.4.4.5 Fill material

330 1.6.3.4.5 Extension of exist precast box culvert < 3.0m

331 1.6.3.4.5.1 Demolition & hacking

332 1.6.3.4.5.2 Earthworks

333 1.6.3.4.5.3 Foundation

334 1.6.3.4.5.4 Precast box culvert

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B6

ID WBS Task Name Duration Start

335 1.6.3.4.5.5 Inlet/ Outlet structures

336 1.6.3.4.5.6 Fill material

337 1.6.3.4.6 Cast insitu box culvert < 3.0m

338 1.6.3.4.6.1 Earthworks

339 1.6.3.4.6.2 Foundation

340 1.6.3.4.6.3 Concreting works

341 1.6.3.4.6.4 Inlet/ Outlet structures

342 1.6.3.4.6.5 Fill material

343 1.6.3.4.7 Extension of exist cast insitu box culvert <3.0m

344 1.6.3.4.7.1 Demolition & hacking

345 1.6.3.4.7.2 Earthworks

346 1.6.3.4.7.3 Foundation

347 1.6.3.4.7.4 Inlet/ Outlet structures

348 1.6.3.4.7.5 Fill material

349 1.6.3.4.8 Surface drains

350 1.6.3.4.8.1 Roadside drain for rural area

351 1.6.3.4.8.2 Roadside drain for urban area

352 1.6.3.4.8.3 Embankment toe drain

353 1.6.3.4.8.4 Interceptor drain

354 1.6.3.4.8.5 Bench drain

355 1.6.3.4.8.6 Berm drain

356 1.6.3.4.8.7 Shoulder drain

357 1.6.3.4.8.8 Cascade drain

358 1.6.3.4.8.9 Median drain for rural area

359 1.6.3.4.8.10 Median drain for urban area

360 1.6.3.4.9 Sub-surface drain

361 1.6.3.4.9.1 Sub soil drain

362 1.6.3.4.10 Sumps

363 1.6.3.4.10.1 Sump at cut

364 1.6.3.4.10.2 Sump at fill

365 1.6.3.4.10.3 Median sum (Rural area)

366 1.6.3.4.10.4 Median sum (Urban area)

367 1.6.3.4.11 Rubble retaining walls

368 1.6.3.4.12 Earth channel excavation

369 1.6.3.4.12.1 Excavation works

370 1.6.3.4.12.2 Protection works

371 1.6.3.5 Culvert & Vehicular Underpass

372 1.6.3.5.1 Temporary Crossing

373 1.6.3.5.1.1 Earthwork

374 1.6.3.5.1.2 Temporary Culvert

375 1.6.3.5.1.2.1 Foundation

376 1.6.3.5.1.2.1.1 Normal foundation

377 1.6.3.5.1.2.1.1.1 Fill

378 1.6.3.5.1.2.1.1.2 Compact

379 1.6.3.5.1.2.1.2 RC Pile

380 1.6.3.5.1.2.1.2.1 Survey

381 1.6.3.5.1.2.1.2.2 Mobilise

382 1.6.3.5.1.2.1.2.3 Test pile

383 1.6.3.5.1.2.1.2.4 Working Pile

384 1.6.3.5.1.2.1.2.5 Cutting off pile head

385 1.6.3.5.1.2.1.2.6 Concreting works

386 1.6.3.5.1.2.1.2.7 As- Built

387 1.6.3.5.1.2.1.2.8 Demobilise

388 1.6.3.5.1.2.1.3 Pressure Treated Timber Pile

389 1.6.3.5.1.2.1.3.1 Mobilization

390 1.6.3.5.1.2.1.3.2 Drive vertical piles.

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B7

ID WBS Task Name Duration Start

391 1.6.3.5.1.2.1.3.3 Cutting off piles head

392 1.6.3.5.1.2.1.3.4 Demobilization

393 1.6.3.5.1.2.2 Precast Pipe Culverts

394 1.6.3.5.1.2.2.1 Supply Precast Pipe Culverts

395 1.6.3.5.1.2.2.2 Install Precast Pipe Culverts

396 1.6.3.5.1.2.3 Inlet / Outlet Structures

397 1.6.3.5.2 Temporary Works

398 1.6.3.5.2.1 Sheet Piles

399 1.6.3.5.2.1.1 Mobilization

400 1.6.3.5.2.1.2 Drive vertical piles.

401 1.6.3.5.2.1.3 Dismantling and removing

402 1.6.3.5.2.1.4 Demobilization

403 1.6.3.5.2.2 River Diversion

404 1.6.3.5.2.2.1 Excavate

405 1.6.3.5.2.2.2 Provide and maintain earth bund

406 1.6.3.5.2.2.3 Water pump work area dry

407 1.6.3.5.3 In-Situ Box Culvert

408 1.6.3.5.3.1 Earthworks

409 1.6.3.5.3.2 Foundation

410 1.6.3.5.3.2.1 Normal Foundation

411 1.6.3.5.3.2.1.1 Fill

412 1.6.3.5.3.2.1.2 Compact

413 1.6.3.5.3.2.2 P.C Spun Pile / RC Pile

414 1.6.3.5.3.2.2.1 Survey

415 1.6.3.5.3.2.2.2 Mobilise

416 1.6.3.5.3.2.2.3 Test pile

417 1.6.3.5.3.2.2.4 Load Test

418 1.6.3.5.3.2.2.4.1 Maintained Load Test

419 1.6.3.5.3.2.2.4.2 PDA

420 1.6.3.5.3.2.2.5 Working Pile

421 1.6.3.5.3.2.2.6 Cutting off pile head

422 1.6.3.5.3.2.2.7 Concreting works

423 1.6.3.5.3.2.2.8 As- Built

424 1.6.3.5.3.2.2.9 Demobilise

425 1.6.3.5.3.3 Miscellaneous

426 1.6.3.5.3.4 Rubber waterstop

427 1.6.3.5.3.5 Dowel bars

428 1.6.3.5.3.6 Filling

429 1.6.3.5.3.6.1 Filling with mining/river sand in layers

430 1.6.3.5.3.6.2 Compaction.

431 1.6.3.5.4 Precast Box Culvert

432 1.6.3.5.4.1 Earthworks

433 1.6.3.5.4.1.1 Excavate, load, haul and deposit to spoil any material

434 1.6.3.5.4.1.2 Excavate, load, haul and deposit to spoil rocks

435 1.6.3.5.4.2 Foundation

436 1.6.3.5.4.2.1 Normal Foundation

437 1.6.3.5.4.2.1.1 Fill

438 1.6.3.5.4.2.1.2 Compact

439 1.6.3.5.4.2.2 P.C Spun Pile / RC Pile

440 1.6.3.5.4.2.2.1 Survey

441 1.6.3.5.4.2.2.2 Mobilise

442 1.6.3.5.4.2.2.3 Test pile

443 1.6.3.5.4.2.2.4 Load Test

444 1.6.3.5.4.2.2.4.1 Maintained Load Test

445 1.6.3.5.4.2.2.4.2 PDA

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B8

ID WBS Task Name Duration Start

446 1.6.3.5.4.2.2.5 Working Pile

447 1.6.3.5.4.2.2.6 Cutting off pile head

448 1.6.3.5.4.2.2.7 Concreting works

449 1.6.3.5.4.2.2.8 As- Built

450 1.6.3.5.4.2.2.9 Demobilise

451 1.6.3.5.4.3 Precast Box Culvert

452 1.6.3.5.4.3.1 Supply Precast Box Culvert

453 1.6.3.5.4.3.2 Install Precast Box Culvert

454 1.6.3.5.4.4 In-situ reinforced concrete for culvert and inlet/outletstructures

455 1.6.3.5.4.4.1 Formwork

456 1.6.3.5.4.4.2 Concreting

457 1.6.3.5.4.4.2.1 Lean concrete

458 1.6.3.5.4.4.2.2 Concrete

459 1.6.3.5.4.4.3 Steel reinforcement

460 1.6.3.5.4.5 Filling

461 1.6.3.5.4.5.1 Filling with mining/river sand in layers

462 1.6.3.5.4.5.2 Compaction.

463 1.6.3.5.5 In-Situ Vehicular Box Culvert

464 1.6.3.5.5.1 Earthworks

465 1.6.3.5.5.1.1 Excavate, load, haul and deposit to spoil any material

466 1.6.3.5.5.1.2 Excavate, load, haul and deposit to spoil rocks

467 1.6.3.5.5.2 P.C Spun Pile / RC Pile

468 1.6.3.5.5.2.1 Survey

469 1.6.3.5.5.2.2 Mobilise

470 1.6.3.5.5.2.3 Test pile

471 1.6.3.5.5.2.4 Load Test

472 1.6.3.5.5.2.4.1 Maintained Load Test

473 1.6.3.5.5.2.4.2 PDA

474 1.6.3.5.5.2.5 Working Pile

475 1.6.3.5.5.2.6 Cutting off pile head

476 1.6.3.5.5.2.7 Concreting works

477 1.6.3.5.5.2.8 As- Built

478 1.6.3.5.5.2.9 Demobilise

479 1.6.3.5.5.3 Miscellaneous

480 1.6.3.5.5.3.1 waterstop

481 1.6.3.5.5.3.2 Joint sealant

482 1.6.3.5.5.3.3 Coating

483 1.6.3.5.5.3.4 Duct pipe

484 1.6.3.6 Slope Protection

485 1.6.3.6.1 Turfing

486 1.6.3.6.2 RE Wall

487 1.6.3.6.3 Guniting

488 1.6.3.6.4 Gabion

489 1.6.3.6.5 Anchor wall

490 1.6.3.7 Pavement Works

491 1.6.3.7.1 Flexible Pavement

492 1.6.3.7.1.1 New Pavement

493 1.6.3.7.1.1.1 Preparation of formation

494 1.6.3.7.1.1.2 Carriageway & paved shoulder

495 1.6.3.7.1.1.2.1 Sub base

496 1.6.3.7.1.1.2.2 Roadbase

497 1.6.3.7.1.1.2.3 Surfacing

498 1.6.3.7.1.1.3 Median & island

499 1.6.3.7.1.1.3.1 Sub base

500 1.6.3.7.1.1.3.2 Roadbase

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B9

ID WBS Task Name Duration Start

501 1.6.3.7.1.1.3.3 Surfacing

502 1.6.3.7.1.1.4 Bus lay by

503 1.6.3.7.1.1.4.1 Sub base

504 1.6.3.7.1.1.4.2 Roadbase

505 1.6.3.7.1.1.4.3 Surfacing

506 1.6.3.7.1.1.5 Access road

507 1.6.3.7.1.1.5.1 Sub base

508 1.6.3.7.1.1.5.2 Roadbase

509 1.6.3.7.1.1.5.3 Surfacing

510 1.6.3.7.1.1.6 Fill material on unpaved shoulder

511 1.6.3.7.1.1.7 Fill material on unpaved median & island

512 1.6.3.7.1.2 Treatment to existing pavement

513 1.6.3.7.1.2.1 Patching

514 1.6.3.7.1.2.2 Miling

515 1.6.3.7.1.2.3 Regulation

516 1.6.3.7.1.2.4 Reconstruction of existing pavement

517 1.6.3.7.1.2.4.1 Mark,cut,breakup, remove & cart away

518 1.6.3.7.1.2.4.2 Sub base

519 1.6.3.7.1.2.4.3 Roadbase

520 1.6.3.7.1.2.5 Overlay

521 1.6.3.7.2 Concrete pavement

522 1.6.3.7.2.1 New pavement

523 1.6.3.7.2.1.1 Preparation of formation

524 1.6.3.7.2.1.2 Carriageway road shoulder

525 1.6.3.7.2.1.2.1 sub base

526 1.6.3.7.2.1.2.2 bond breaking treatment

527 1.6.3.7.2.1.2.3 Concrete pavement

528 1.6.3.7.2.1.2.4 Construction joint

529 1.6.3.7.2.1.2.5 texturing

530 1.6.3.7.2.1.2.6 curing compound

531 1.6.3.7.2.1.2.7 silicone sealant

532 1.6.3.7.2.1.2.8 anchor beam

533 1.6.3.7.2.1.2.9 movable shaded cover

534 1.6.3.7.2.1.2.10 surface stamp

535 1.6.3.7.2.1.3 fill material on unpaved shoulder

536 1.6.3.7.2.1.4 filter material

537 1.6.3.8 Road Furniture

538 1.2.9 SIGNBOARDS

539 1.1.1 Destination Signboard

540 1.1.2 Gantry Directional Signboard

541 1.1.3 Butterfly gantry

542 1.1.4 Warning and Regulatory Traffic signs

543 1.2 TRAFFIC BARRIER

544 1.2.1 Guardrails

545 1.2.1.1 Single mounted corrugated steel beam guardrail inclusive of delineators.

546 1.2.1.2 Double mounted corrugated steel beam guardrail inclusive of delineators.

547 1.2.1.3 Guardrail Ends

548 1.2.2 New Jersey Barrier (NJB)

549 1.2.3 Wire rope

550 1.3 ROAD MARKING

551 1.3.1 Hot-applied superimposed reflectorised thermoplastic road markings

552 1.3.2 Directional Arrow for roads in urban area

553 1.3.3 Directional Arrow for roads in rural area

554 1.4 BUS-SHELTER

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B10

ID WBS Task Name Duration Start

555 1.5 MS RAILING

556 1.6 ANTIGLARE SCREEN

557 1.7 INTERLOCKING PAVING BLOCK FOR

558 1.9 CONCRETE KERB

559 1.10 DELINEATORS

560 1.12 IMPACT ATTENUATOR

561 1.13 RIGHT OF WAY MARKER

562 1.6.3.9 Pedestrian Bridge

563 1.1 PRESTRESSED BEAM / BOX GIRDER / POST-TENSION PRESTRESSED BEAM

564 1.1.1 Earthwork

565 1.6.3.9.1.2 PILING

566 1.6.3.9.1.2.1 P.C Spun Pile / RC Pile

567 1.6.3.9.1.2.1.1 Survey

568 1.6.3.9.1.2.1.2 Mobilise

569 1.6.3.9.1.2.1.3 Test pile

570 1.6.3.9.1.2.1.4 Load Test

571 1.6.3.9.1.2.1.4.1 Maintained Load Test

572 1.6.3.9.1.2.1.4.2 PDA

573 1.6.3.9.1.2.1.5 Working Pile

574 1.6.3.9.1.2.1.6 Cutting off pile head

575 1.6.3.9.1.2.1.7 Concreting works

576 1.6.3.9.1.2.1.8 As- Built

577 1.6.3.9.1.2.1.9 Demobilise

578 1.6.3.9.1.2.2 Micro Pile

579 1.6.3.9.1.2.2.1 Survey

580 1.6.3.9.1.2.2.2 Mobilise

581 1.6.3.9.1.2.2.3 Test pile

582 1.6.3.9.1.2.2.3.1 Drilled hole with temp.casing

583 1.6.3.9.1.2.2.3.2 Supply & install permanent casing

584 1.6.3.9.1.2.2.3.3 Supply & place cement grout

585 1.6.3.9.1.2.2.3.4 Cutting off pile head

586 1.6.3.9.1.2.2.4 Load Test

587 1.6.3.9.1.2.2.4.1 Maintained Load Test

588 1.6.3.9.1.2.2.4.2 PDA

589 1.6.3.9.1.2.2.5 Working pile

590 1.6.3.9.1.2.2.5.1 Drilled hole with temp.casing

591 1.6.3.9.1.2.2.5.2 Supply & install permanent casing

592 1.6.3.9.1.2.2.5.3 Supply & place cement grout

593 1.6.3.9.1.2.2.5.4 Cutting off pile head

594 1.6.3.9.1.2.2.6 As-Built

595 1.6.3.9.1.2.2.7 Demobilise

596 1.6.3.9.1.3 Excavate & remove

597 1.6.3.9.1.4 Soil-Anti Termite Treatment

598 1.6.3.9.1.5 Pile Cap

599 1.6.3.9.1.6 Column Stump

600 1.1.3 Precast Prestressed

601 1.1.3.1 Beam

602 1.1.3.2 Box Girder

603 1.1.3.3 Stair case/Ramp

604 1.1.4 Post Tension

605 1.1.5.1 Pier

606 1.1.5.2 Cross Beam

607 1.1.5.3 Staircase/Ramp

608 1.1.6 Miscellaneous

609 1.2 Steel Truss

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B11

ID WBS Task Name Duration Start

610 1.2.1 Earthwork

611 1.6.3.9.8.2 Piling

612 1.6.3.9.8.2.1 P.C Spun Pile / RC Pile

613 1.6.3.9.8.2.1.1 Survey

614 1.6.3.9.8.2.1.2 Mobilise

615 1.6.3.9.8.2.1.3 Test pile

616 1.6.3.9.8.2.1.4 Load Test

617 1.6.3.9.8.2.1.4.1 Maintained Load Test

618 1.6.3.9.8.2.1.4.2 PDA

619 1.6.3.9.8.2.1.5 Working Pile

620 1.6.3.9.8.2.1.6 Cutting off pile head

621 1.6.3.9.8.2.1.7 Concreting works

622 1.6.3.9.8.2.1.8 As- Built

623 1.6.3.9.8.2.1.9 Demobilise

624 1.6.3.9.8.2.2 Micro Pile

625 1.6.3.9.8.2.2.1 Survey

626 1.6.3.9.8.2.2.2 Mobilise

627 1.6.3.9.8.2.2.3 Test pile

628 1.6.3.9.8.2.2.3.1 Drilled hole with temp.casing

629 1.6.3.9.8.2.2.3.2 Supply & install permanent casing

630 1.6.3.9.8.2.2.3.3 Supply & place cement grout

631 1.6.3.9.8.2.2.3.4 Cutting off pile head

632 1.6.3.9.8.2.2.4 Load Test

633 1.6.3.9.8.2.2.4.1 Maintained Load Test

634 1.6.3.9.8.2.2.4.2 PDA

635 1.6.3.9.8.2.2.5 Working pile

636 1.6.3.9.8.2.2.5.1 Drilled hole with temp.casing

637 1.6.3.9.8.2.2.5.2 Supply & install permanent casing

638 1.6.3.9.8.2.2.5.3 Supply & place cement grout

639 1.6.3.9.8.2.2.5.4 Cutting off pile head

640 1.6.3.9.8.2.2.6 As-Built

641 1.6.3.9.8.2.2.7 Demobilise

642 1.2.3 In- situ Reinforced Concrete

643 1.2.3.1 Pier

644 1.2.3.2 Cross Beam

645 1.2.3.3 Staircase/Ramp

646 1.2.4 Structural Steel

647 1.2.5 Miscellaneous

648 1.3 Pedestrian Underpass

649 1.3.1 Earthwork

650 1.3.2 Foundation

651 1.3.3 Precast reinfirced Concrete Pile

652 1.3.4 Precast Box Pedestrian Underpass

653 1.3.5 Filling

654 1.3.6 Electrical

655 1.6.3.10 Plumbing

656 1.6.3.11 Fencing

657 1.6.3.12 Water

658 1.6.3.13 Sewerage

659 1.6.3.14 Bridge Structure

660 1.6.3.14.1 Sub-structure

661 1.6.3.14.1.1 Temporary Works

662 1.1.1 Sheet piles

663 1.1.1.1 Mobilization

664 1.1.1.3 Piling of FSP IVA

665 1.1.2 Excavation & Dewatering

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B12

ID WBS Task Name Duration Start

666 1.1.2.1 Excavate & remove dispose soil

667 1.1.2.2 Prepare dry platform

668 1.1.2.3 Water pump & construc earth drain

669 1.1.3 Walling & Strutting

670 1.1.3.1 Assembling

671 1.1.3.2 Removal

672 1.1.4 Removal of temporary works

673 1.1.5 Temporary steel platform

674 1.6.3.14.1.2 Abutment

675 1.2.1 Earthwork

676 1.2.1.1 Excavate

677 1.2.1.3 Fill, spread, grade & compact

678 1.2.1.4 Supply, spread, level & compact behind abutment/wingwall

679 1.2.1.7 Rock filled gabion

680 1.2.1.8 PVC outlet drain pipes

681 1.2.1.9 Perforated seepage pipe

682 1.2.1.10 20mm-40mm crushed stones

683 1.2.1.11 Concreting Works

684 1.2.1.12 Bituminous coating

685 1.2.2.5 Insitu parapet

686 1.6.3.14.1.3 Piers

687 1.3.1 Earthwork

688 1.3.1.1 Excavate, load, haul & dispose materials

689 1.3.1.2 Fill, spread, grade & compact

690 1.6.3.14.1.3.2 PILING

691 1.6.3.14.1.3.2.1 P.C Spun Pile / RC Pile

692 1.6.3.14.1.3.2.1.1 Survey

693 1.6.3.14.1.3.2.1.2 Mobilise

694 1.6.3.14.1.3.2.1.3 Test pile

695 1.6.3.14.1.3.2.1.4 Load Test

696 1.6.3.14.1.3.2.1.4.1 Maintained Load Test

697 1.6.3.14.1.3.2.1.4.2 PDA

698 1.6.3.14.1.3.2.1.5 Working Pile

699 1.6.3.14.1.3.2.1.6 Cutting off pile head

700 1.6.3.14.1.3.2.1.7 Concreting works

701 1.6.3.14.1.3.2.1.8 As- Built

702 1.6.3.14.1.3.2.1.9 Demobilise

703 1.6.3.14.1.3.2.2 Micro Pile

704 1.6.3.14.1.3.2.2.1 Survey

705 1.6.3.14.1.3.2.2.2 Mobilise

706 1.6.3.14.1.3.2.2.3 Test pile

707 1.6.3.14.1.3.2.2.3.1 Drilled hole with temp.casing

708 1.6.3.14.1.3.2.2.3.2 Supply & install permanent casing

709 1.6.3.14.1.3.2.2.3.3 Supply & place cement grout

710 1.6.3.14.1.3.2.2.3.4 Cutting off pile head

711 1.6.3.14.1.3.2.2.4 Load Test

712 1.6.3.14.1.3.2.2.4.1 Maintained Load Test

713 1.6.3.14.1.3.2.2.4.2 PDA

714 1.6.3.14.1.3.2.2.5 Working pile

715 1.6.3.14.1.3.2.2.5.1 Drilled hole with temp.casing

716 1.6.3.14.1.3.2.2.5.2 Supply & install permanent casing

717 1.6.3.14.1.3.2.2.5.3 Supply & place cement grout

718 1.6.3.14.1.3.2.2.5.4 Cutting off pile head

719 1.6.3.14.1.3.2.2.6 As-Built

720 1.6.3.14.1.3.2.2.7 Demobilise

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B13

ID WBS Task Name Duration Start

721 1.6.3.14.1.3.2.3 Bore Pile

722 1.6.3.14.1.3.2.3.1 Survey

723 1.6.3.14.1.3.2.3.2 Mobilise

724 1.6.3.14.1.3.2.3.3 Test Pile

725 1.6.3.14.1.3.2.3.3.1 Drilled hole with temp.casing

726 1.6.3.14.1.3.2.3.3.2 Supply & install permanent casing

727 1.6.3.14.1.3.2.3.3.3 Reinforcement

728 1.6.3.14.1.3.2.3.3.4 Concreting works

729 1.6.3.14.1.3.2.3.3.5 Cutting off pile head

730 1.6.3.14.1.3.2.3.4 Load Test

731 1.6.3.14.1.3.2.3.4.1 Statnamic test

732 1.6.3.14.1.3.2.3.4.2 Penetration test

733 1.6.3.14.1.3.2.3.4.3 PDA

734 1.6.3.14.1.3.2.3.4.4 Integrity test

735 1.6.3.14.1.3.2.3.5 Working Pile

736 1.6.3.14.1.3.2.3.5.1 Drilled hole with temp.casing

737 1.6.3.14.1.3.2.3.5.2 Supply & install permanent casing

738 1.6.3.14.1.3.2.3.5.3 Reinforcement

739 1.6.3.14.1.3.2.3.5.4 Concreting works

740 1.6.3.14.1.3.2.3.5.5 Cutting off pile head

741 1.6.3.14.1.3.2.3.6 As-Built

742 1.6.3.14.1.3.2.3.7 Demobilise

743 1.6.3.14.1.3.2.4 Steel H / Steel Pipe - Pile

744 1.6.3.14.1.3.2.4.1 Survey

745 1.6.3.14.1.3.2.4.2 Mobilise

746 1.6.3.14.1.3.2.4.3 Initial pile

747 1.6.3.14.1.3.2.4.4 Extention Pile

748 1.6.3.14.1.3.2.4.5 Cutting off pile head

749 1.6.3.14.1.3.2.4.6 Load Test

750 1.6.3.14.1.3.2.4.6.1 Maintained Load Test

751 1.6.3.14.1.3.2.4.6.2 PDA

752 1.6.3.14.1.3.2.4.7 As-Built

753 1.6.3.14.1.3.2.4.8 Demobilise

754 1.6.3.14.2 Super Structure

755 1.6.3.14.2.1 Steel Beam Bridge

756 1.6.3.14.2.1.1 Steel Beam

757 1.6.3.14.2.1.2 Concrete Deck Slab

758 1.6.3.14.2.1.3 Precast concrete parapets

759 1.6.3.14.2.1.4 Install GI posts and handrails

760 1.6.3.14.2.1.5 Install UPVC outlet drain pipe including all necessary accessories

761 1.6.3.14.2.1.6 Bearing

762 1.6.3.14.2.1.6.1 Install laminated elastomeric bearing

763 1.6.3.14.2.1.6.2 Test Bearing

764 1.6.3.14.2.2 Pre-Tensioned Prestressed Beam Bridge

765 1.6.3.14.2.2.1 Pretensioned Prestressed Beam

766 1.6.3.14.2.2.1.1 Pre-Tensioned Prestressed Beams

767 1.6.3.14.2.2.1.2 Transverse prestressing cables for diaphragms

768 1.6.3.14.2.2.2 Concrete Deck Slab

769 1.6.3.14.2.2.3 Precast concrete parapets

770 1.6.3.14.2.2.4 Install GI posts and handrails

771 1.6.3.14.2.2.5 Install UPVC outlet drain pipe including all necessary accessories

772 1.6.3.14.2.2.6 Bearing

773 1.6.3.14.2.2.6.1 Install laminated elastomeric bearing

774 1.6.3.14.2.2.6.2 Test Bearing

775 1.6.3.14.2.3 Post- Tensioned Prestreesed Beam Bridge

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B14

ID WBS Task Name Duration Start

776 1.6.3.14.2.3.1 Post-tensioned Prestressed Beam

777 1.6.3.14.2.3.1.1 Post-tensioned Prestressed beams

778 1.6.3.14.2.3.1.2 Transverse prestressing cables for diaphragms

779 1.6.3.14.2.3.2 Concrete Deck Slab

780 1.6.3.14.2.3.3 Precast concrete parapets

781 1.6.3.14.2.3.4 Install GI posts and handrails

782 1.6.3.14.2.3.5 Install UPVC outlet drain pipe including all necessary accessories

783 1.6.3.14.2.3.6 Bearing

784 1.6.3.14.2.3.6.1 Install laminated elastomeric bearing

785 1.6.3.14.2.3.6.2 Test Bearing

786 1.6.3.14.2.4 Voided Slab

787 1.6.3.14.2.4.1 Install temporary scaffolding

788 1.6.3.14.2.4.2 Voided Slab

789 1.6.3.14.2.4.3 Precast concrete parapets

790 1.6.3.14.2.4.4 Install GI posts and handrails

791 1.6.3.14.2.4.5 Install UPVC outlet drain pipe including all necessary accessories

792 1.6.3.14.2.4.6 Bearing

793 1.6.3.14.2.4.6.1 Iinstall laminatedmechanical pot bearing

794 1.6.3.14.2.4.6.2 Test Pot Bearing

795 1.6.3.14.2.5 Precast Box Girder - Incrimental Launching

796 1.6.3.14.2.5.1 Bridge Deck

797 1.6.3.14.2.5.2 Testing of concrete

798 1.6.3.14.2.5.3 Precast concrete parapets

799 1.6.3.14.2.5.4 Install GI posts and handrails

800 1.6.3.14.2.5.5 Install UPVC outlet drain pipe including all necessary accessories

801 1.6.3.14.2.5.6 H.D galvanised steel brackets and hangers

802 1.6.3.14.2.5.7 H.D galvanised heavy duty door grills

803 1.6.3.14.2.5.8 Install G.I catladder

804 1.6.3.14.2.5.9 Bearing

805 1.6.3.14.2.5.9.1 Iinstall laminatedmechanical pot bearing

806 1.6.3.14.2.5.9.2 Test Pot Bearing

807 1.6.3.14.2.6 Cast In Situ Box Girder Balanced Cantilever

808 1.6.3.14.2.6.1 Temporary Works

809 1.6.3.14.2.6.2 Segmental Box Girder and Ancillaries

810 1.6.3.14.2.6.3 Testing of concrete

811 1.6.3.14.2.6.4 Precast concrete parapets

812 1.6.3.14.2.6.5 Install GI posts and handrails

813 1.6.3.14.2.6.6 Install UPVC outlet drain pipe including all necessary accessories

814 1.6.3.14.2.6.7 H.D galvanised steel brackets and hangers

815 1.6.3.14.2.6.8 H.D galvanised heavy duty door grills

816 1.6.3.14.2.6.9 Install G.I catladder

817 1.6.3.14.2.6.10 Supply and install Inspection platform at pier

818 1.6.3.14.2.6.11 Bearing

819 1.6.3.14.2.6.11.1 Install laminated mechanical pot bearing

820 1.6.3.14.2.6.11.2 Test Pot Bearing

821 1.6.3.14.2.7 Precast Segmental Box Girder- Balanced Cantilever

822 1.6.3.14.2.7.1 Temporary Works

823 1.6.3.14.2.7.2 Precast Segmental Box Girder and Ancillaries

824 1.6.3.14.2.7.3 Testing of concrete

825 1.6.3.14.2.7.4 Precast concrete parapets

826 1.6.3.14.2.7.5 Install GI posts and handrails

827 1.6.3.14.2.7.6 Install UPVC outlet drain pipe including all necessary accessories

828 1.6.3.14.2.7.7 H.D galvanised steel brackets and hangers

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B15

ID WBS Task Name Duration Start

829 1.6.3.14.2.7.8 H.D galvanised heavy duty door grills

830 1.6.3.14.2.7.9 Install G.I catladder

831 1.6.3.14.2.7.10 Bearing

832 1.6.3.14.2.7.10.1 Iinstall laminatedmechanical pot bearing

833 1.6.3.14.2.7.10.2 Test Pot Bearing

834 1.6.3.15 Elektrikal

835 1.6.3.15.1 Underground cable

836 1.6.3.15.2 Road Lighting

837 1.6.3.15.3 Feeder Pillar

838 1.6.3.15.4 Traffic Light

839 1.6.3.15.5 Testing

840 1.7 As-Built

841 1.8 Site Clearance

842 1.9 HANDING OVER

TEMPLAT WBS BAGI PROJEK JALAN (2018)

Unit Amalan Terbaik, CPAB | Page B16