RER12

-

Upload

sopna-balakrishnan -

Category

Documents

-

view

124 -

download

0

Transcript of RER12

[Type the document title] [Year]

UNIVERSITI TEKNIKAL MALAYSIA MELAKA

FAKULTI KEJURUTERAAN ELEKTRONIK DANKEJURUTERAAN KOMPUTER

LAPORAN LATIHAN INDUSTRI

Nama pelajar : Sopna a/p Balakrishnan Kursus : Sarjana Muda Kejuruteraan Elektronik (Elektronik Telekomunikasi) Tahun : 2012 Tarikh latihan : 2 July 2012– 7 September 2012

Nama Syarikat : JVC Manufacturing Malaysia

INDUSTRY TRAINING REPORTAT

JVC MANUFACTURING MALAYSIA

Period Of Training:02/07/2012– 07/09/2012

Submitted By:Sopna d/o Balakrishnan

This industrial training report is submitted to Faculty of Electronics and Computer Engineering,

Universiti Teknikal Malaysia MelakaIn partial fulfillment for Bachelor of Engineering

Faculty of Electronics and Computer Engineering Universiti Teknikal Malaysia Melaka

September 20122

PERAKUAN

Laporan ini adalah hasil usaha saya sendiri dan telah disahkan isi kandungannya

oleh pihak industri sebagai satu laporan lengkap setelah tamat menjalani latihan industri

dalam tempoh yang telah ditetapkan.

Tandatangan : ………………………………

Nama Pelajar : Sopna a/p Balakrishnan

Tarikh : 1 September 2012

Disahkan Oleh :

(Penyelia Industri)

Tandatangan : ………………………………

Nama Penyelia :

Jawatan :

Cop Syarikat :

Tarikh :

_________________________________________________________________________

___

Diperiksa Oleh :

(Penyelia Fakulti)

Tandatangan : ………………………………

Nama Penyelia :

Tarikh :

3

ABSTRACT

All bachelor degree students are required to undergo industrial training for 10 weeks as part

of their curriculum to complete their 4 year course for the Bachelor of Electronic

Engineering. The attachment will be during the short semester of their study. During the 20

weeks period of training, students will be supervised and monitored their training by a

nominated supervisor.

For my Industrial Training, I was given opportunity to pursue of my 10 weeks internship

program in JVC Manufacturing Malaysia. JVC Manufacturing Malaysia Sdn Bhd "JMM"

was established on May 1989 and located in Shah Alam, Selangor Malaysia. As the major

manufacturer and assembler of Camcorder, they are fully committed to preserve the

environment. In order to ensure a systematic environmental system, JMM had been

certified with the ISO14001:2004 Standard by Lloyds Register (UKAS) since 1999 and

being continuously updated till today. The Environmental /ISO 14001 committee are now

actively involved in Environmental Project such as Save Energy, Save Water, Waste

Control and Recycling Activities.

For past two months, I was assigned under Research & Development Department classified

to Electrical Department which is in charge by Mr Lm, but the trainees was assigned to Mr

Ho. For first five weeks, I was assigned to Audio department later on I was assigned to

power supply department. My daily routine is to obey the company rules and assist the

engineers with their workload.

4

ACKNOWLEDGEMENTS

Firstly I like to thank you to my family for allowing me to take Bachelor Degree in

Electronic Telecommunication. Then my gratitude goes to both my academic supervisor

and Industrial supervisor for the guidance trough out the industrial training. I would like to

thanks to the JVC Manufacturing Malaysia for allowing me to join the company temporally

for my industrial training.

My gratitude goes to the Chief Engineer and Assistance Engineer. Then I would like to

thank to the Dean of the Electronic Faculty and all the staff that involve directly or

indirectly in the industrial training. Finally I was able to complete this industrial training

and the final report with the help of the instructor that is the employers of the company.

5

ABSTRACT........................................................................................................................................................4

ACKNOWLEDGEMENTS...............................................................................................................................5

CHAPTER 1: INTRODUCTION.....................................................................................................................7

1.1 BRIEFING TO INDUSTRIAL TRAINING..................................................................................................71.2 OBJECTIVE OF INDUSTRIAL TRAINING................................................................................................71.3 OBJECTIVE OF THIS REPORT................................................................................................................81.4 IMPORTANCE OF INDUSTRIAL TRAINING............................................................................................81.5 SCOPE OF INDUSTRIAL TRAINING........................................................................................................9

CHAPTER 2: ORGANIZATION BACKGROUND.....................................................................................11

2.1 HISTORY OF ESTABLISHMENT............................................................................................................112.2 VISION, MISSION AND OBJECTION OF ORGANIZATION....................................................................122.3 TYPE OF INDUSTRY/ BUSINESS...........................................................................................................132.4 CORE ACTIVITIES...............................................................................................................................132.5 DEPARTMENT DIVISION......................................................................................................................162.6 TASK AND RESPONSIBILITY OF DEPARTMENT..................................................................................172.7 GENERAL OPERATION........................................................................................................................18

CHAPTER 3: THE TRAINING PROGRAMME.........................................................................................20

3.1 AUDIO TESTING IN ANECHOIC CHAMBERS.......................................................................................203.2 MR SENSOR CHECKING.....................................................................................................................223.3 CHECKING LINEARITY IN TOUCH PANEL..........................................................................................363.4 CHECKING OVERALL RESISTANCE FOR TOUCH PANEL.....................................................................44

CHAPTER 4: CONCLUSIONS AND SUGGESTIONS..............................................................................48

4.1 CONCLUSION.......................................................................................................................................494.2 Suggestions for Final Year Project...................................................................................................49

6

CHAPTER 1: INTRODUCTION

1.1 Briefing to Industrial Training

Industrial Training is a scope which is a syllabus to the each student in IPTA level

weather for diploma or degree and UTeM also one of them. It is compulsory for an

UTeM student to pass the industrial training before being awarded the degree or

diploma in their course. Each student must complete the whole duration period i.e.

10 weeks for Degree course and 10 weeks Diploma course and not permitted to end

the training earlier than the specified.

The main of objective of Industrial Training is to expose to actual working

environment whereby students will encounter new problems and challenges.

1.2 Objective of Industrial Training

I. To expose students to actual working environment soon.

II. To enhance students knowledge and skill.

III. To instill the qualities of integrity, responsibility and self-confidence.

IV. To expose students to safe practices and regulations in the industry.

V. To instill spirit of teamwork and good relationship between student and

fellow workers.

7

VI. To assess student ability and competency in their preparation to join the

workforce upon completion of their studies in UTeM

1.3 Objective of this report

I. To document the all activities during industrial training.

II. To prove to lecturer that the student have complete the industrial training.

III. To generate new idea to resolve the problem.

1.4 Importance of Industrial Training

Industrial Training is one of the aspects which importance to the student to instil

higher sprit and confidence level in their self when joins in actual working

environment soon. Besides that, student will make comparison what they learn at

UTeM with the jobs while industrial training. The will know whether what they

studies is learn or not and it most benefit for their experience.

During industrial training, student needs to instil the qualities of integrity,

responsibility, open minded, inquires and self-confidence will in their self it will

make student to done the works perfectly and smoothly. Relationship student and

employee need to close. The student can ask anything what they not understand

easily. So the student can get more information for their knowledge and experience.

8

To the students who were passed for industrial training they will feel difference in

their self. With the skill and experience which they learn during industrial training

will make them more confidence to join in what ever they do because the skill and

experience very benefit to them when join in actual working environments soon.

1.5 Scope of Industrial Training

During industrial training I did obtain on :

I. Learn how job in oil industry.

II. Improve skill of welding and cutting.

III. Learn the work of workshop.

IV. Get knowledge in maintained field.

V. Get knowledge about how many component/parts.

VI. Learn about calculation in engineering field.

9

CHAPTER 2: ORGANIZATION BACKGROUND

2.1 History of Establishment

JVC was established in 1927 as the Japanese arm of Victor Talking Machine Company in

the U.S. and started out as a manufacturer and wholesaler of phonographs and records. The

famous His Master’s Voice image, the adorable dog “Nipper” sitting in front of a

phonograph with his head cocked to one side, was a symbol of the spirit of development at

the time the Company was founded.

JVC started out as a manufacturer and wholesaler of phonographs and records and

expanded its business to the production of radio receivers, eventually branching out into the

image business on top of the sound business, including the development of the first TV

broadcast receiver in Japan in 1939. Joined by Kenjiro Takayanagi, who has become

known as “the Father of Japanese Television,” after the war, JVC laid the basis for growing

into a technology development-oriented company that has an original mindset and is

recognized by the global market for its achievements, including the development of the 45-

45 stereo system in 1956 and the world’s first 2-headed VCR in 1959, in addition to the

development of television. In 1976, JVC released VHS home video recorders, which are

still used by many families around the world as Japan’s first global standard.

The nucleus of this technology has been handed down through the Company and has

become the foundation for the development of various world-first and industry-first

products such as the industry’s first 16:9 wide aspect television in 1991, the world’s first

10

high-definition home video camera in 2003 and the world’s first full 1920 x 1080 high-

definition resolution home video camera in 2007.

One of the advantages of JVC, as just described, is the superior visual and audio

technologies that it has cultivated over the years. In 2009, these technologies were seasoned

with creativity and amusement. Using our enhanced advantages, we as a new JVC will

provide proprietary proposals worldwide. In line with this initiative, we have adopted our

global brand JVC for the first time in Japan. JVC uses its superior audio and visual

technologies and communications networks to create new ways to communicate through

music and images vehicles that inspire people and expand the possibilities for creative

expression. The thinking behind the JVC brand statement “The Perfect Experience” is our

commitment to use superior technologies to create products that create truly moving

experiences and provide total satisfaction for our customers, in addition to providing

customers with the potential for personal enrichment and lifetime satisfaction by using our

products.

2.2 Vision, Mission and Objection of Organization

JVC KENWOOD established a new corporate logo that expresses its new vision

“Creating excitement and peace of mind for the people of the world.”

Figure 1

11

They made the logo simple and refined to bring out a feeling of history and tradition, and to

instill a calm confidence and sense of security in those who view the logo. Notwithstanding

the logo’s simple expression, the curved lines and roundness of characters symbolize

“excitement,” and stable boldfaced characters are symbolic of “peace of mind.” Thus, the

desire of JVC KENWOOD to realize its vision of “Creating excitement and peace of mind”

is embodied into the logo.

2.3 Type of Industry/ Business

JVC is a world leader in audiovisual and related software products. The Company is

being transformed from an audiovisual innovator to a digital systems integrator. Its

position as one of the few companies in the world with large-scale operations in

both hardware and software, along with the innovative technology that led to the

development of VHS, provides JVC with a competitive advantage in the

development of digital systems. Based on these strengths, JVC looks forward to a

new stage of growth in the multimedia age.

2.4 Core Activities

With regard to business operations, we will focus on our strengths of image technologies,

acoustic technologies, radio equipment, and audio and visual software, using these as the

core of our aims to become a business group whose sound, images, and radio

communications products and drivers make communication a reality for the people of the

world.

12

In order to do this, we plan to implement a growth-oriented investment strategy in the

respective domains of car electronics, radio equipment, cameras, imaging equipment, sound

equipment, and audio and visual software. In addition, through maximizing the efficacy of

our unification as an integrated company, we also intend to expand the contents of our

business to products both simple and complex, to solutions and to devices.

Furthermore, while making the best use of the domain of “excitement” that the brands of

JVC, KENWOOD, and Victor are known for, we also hope to expend into the domain of

“peace of mind,” which is what will be in demand in the demand in the days to come. In

doing so, we intend to shift our foothold from the “Business to Consumer” attitude to one

of “Business to Business, Professional to professional” and from the mass market to the

custom/niche markets.

We will further concentrate management resources on the Car Electronics and Professional

System businesses, among others, where we can demonstrate our strengths to the maximum

extent possible as a global specialized manufacturer. In addition, we will make products for

the medical and education fields as well as products that address concerns about an aging

population, ecology and security/safety. These changes will contribute to the Car

Electronics and Professional System businesses in the future. As for the Home & Mobile

Electronics business, which faces fierce competition, we will shift our emphasis form

products for the mass market to those for professional users and to niche markets while

using visual and audio technologies that are also used in Professional Systems.

13

The Entertainment business, the only software business that creates content of

“excitement,” will shift business domains from music/video packages to comprehensive

entertainment. Through these measures, we will transition from our current unified vision

“Realize The Unconventional,” into “excitement and Peace of Mind for People

Worldwide,” This will be the corporate vision for our unified company, and along with the

revised focus of our resources, we will pursue profitable growth under the mid-term

business plan that will last through the year ending March 2013.

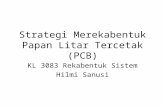

2.5 Department Division

14

Figure 2

2.6 Task and Responsibility of Department

15

For R&D Department, it divides by 2 groups.

Audio (Radio) : divide by 3 division

Video (Camcorder) : divide by 3 division

Three (3) divisions in audio and video group:

Electrical Division

Involve in electrical design, evaluation and countermeasure.

Design the main system circuit-core IC interfacing, power circuit; make

related software spec, new component evaluation.

Follow-up, testing and trouble-shooting of electrical related problem until

pre-production stage.

Co-ordinate and co-operate with other teams to ensure design is completed

within development cycle schedule.

Meet the design objective for quality, timing of introduction, cost.

Cosmetic Division

Design & develop mechanical parts.

Troubleshoot any design related problems & solve with effective solutions.

Perform reliability tests.

Responsible for-engineering (VE) application.

16

Software Division

Design & develop software for Digital Video Camera products

Product features/functions specification making

Design &develop software (documentation and source coding)

Evaluate operation and performance of the product

Problem solving and debugging by development tools

Cooperation with other teams to ensure design is completed within development

cycle schedule

Design function specifications and software test sheets and perform software

evaluation

Evaluate operation and performance of the product

2.7 General Operation

JVC Sales & Service Malaysia is a wholly owned subsidiary of Victor Company of Japan,

Limited. JVC is one of the world's leading developers and manufacturers of sophisticated

audio, video and related software products. Building upon a wealth of technologies,

exemplified by the JVC-invented VHS videocassette recorder, the Company is moving

decisively to offer appropriate solutions for the multimedia age. To remain at the forefront

of the audiovisual industry into the 21st century, JVC is marshalling its resources to create

the ultimate in appealing, cost-competitive products.

17

JVC Sales & Service Malaysia is currently marketing products in the following categories:

Digital Video Camcorders, VHS-C Camcorders, Digital Still Cameras,

DVD/SVCD/VCD/CD/MD Players, Super VHS VCR's, VHS VCR's, Colour Televisions,

Home Audio Components and Systems, Personal Audio Systems, Mobile Audio Systems

and Blank Video and Audio Tapes. JVC is creating new business opportunities by

strengthening its line-up of high-value-added products that incorporate digital technology.

JVC Professional Products Company distributes a complete line of broadcast, professional

and presentation equipment, including cameras, VTRs, editing equipment, D-ILA and LCD

projectors, visual presenters, monitors and computer products.

JVC Sales & Service Malaysia also has service and parts centers across Malaysia and is

committed to serving our customers. Throughout more than seventy years, the JVC brand

name has been associated with the very best in entertainment, music, and sporting events.

Annual sponsorships of the world-renown JVC Tokyo Video Festival and the JVC Jazz

Festival have helped attract the attention of millions of customers.

18

CHAPTER 3: THE TRAINING PROGRAMME

3.1 Audio Testing in Anechoic Chambers

Since I was situated in Audio Department, my job was practically to assist engineers in

testing the quality of the new product that will be available in market by end of this year.

To perform an audio test, it must be perform in an anechoic chamber. An anechoic chamber

(an-echoic meaning non-echoing or echo-free) is a room designed to stop reflections of

either sound or electromagnetic waves. They are also insulated from exterior sources of

noise. The combination of both aspects means they simulate quiet open-space of infinite

dimension, which is useful when exterior influences, would otherwise give false results

The ideal anechoic chamber is a room totally free of acoustical reverberations. Any sound

projected into the room, at any frequency, is fully absorbed. Anechoic chambers are meant

to simulate something that we refer to as “free field”; that is a noise field that is completely

free of any reflected acoustical energy. Think of it this way… If I stand in the middle of a

vast field and shout at the top of my lungs whatever I say won’t come back to me as an

echo; however if I stand in the middle of a gymnasium and shout the same thing I’ll hear all

kinds of echoing as the sound bounces from surface to surface. These chambers allow us to

measure just the initial sound and none of those echoes. These chambers also are designed

to isolate noises from outside sources to ensure that your measurements are not

contaminated.

19

Of course, no anechoic chamber is perfect. It helps to build the room as large as possible:

the inverse square law dictates that sound energy will dissipate, so each square foot of

internal surface will have less energy to absorb. Conversely, a smaller room will require

more or better sound absorption material to have the same effect. This is particularly true of

bass frequencies, and that's why smaller chambers only have effective absorption down to a

certain limit-perhaps 100Hz or so.

The effectiveness of an anechoic chamber is measured in dB of rejection, which is the ratio

of direct sound to reflected sound inside the room. The new Meyer Sound chamber

provides better than 80dB rejection from 20kHz down to 80Hz, which is excellent

performance for a medium-sized chamber. True, we still go outdoors for tests below 80Hz.

But outdoor tests at higher frequencies are notoriously unreliable because of wind and

temperature shifts. For the critical middle and upper octaves, an indoor chamber remains

the only truly reliable tool for accurate measurement.

The testing that I perform required a speaker, cable that will connect from the product to

audio analyzer. During the testing, I varied the audio frequency that is emitted by the

speaker, then the camcorder reads the audio and sends the information to audio analzer,

which is situated outside of the chamber. Audio Frequency is varied according to human

hearing range, which are 20Hz- 20KHz.

20

Figure 3

3.2 MR Sensor Checking

I managed to assist an engineer in checking MR sensor. The MR sensor uses the

magnetoresistive effect. The sensor has a CMOS IC covered with a thin film made of an

alloy including ferromagnetic metal such as Ni and Fe as its principal elements.

Strong thin-film ferromagnetic metal generates a resistance that varies with the strength of

an external magnetic field in a specific direction. The MR sensor uses such an effect. This

sensor is made form a magnetic resistance effect element (MR element). The change in the

magnetic field and the existence of the magnetic substance can be known as a change in the

21

voltage. The phenomenon that solid electric resistance changes by the magnetic field. See

the drawing. The MR sensor has strong thin-film ferromagnetic metal of a specific shape

based on the principle for detecting the direction of a magnetic field in the saturation

sensibility region. The elements of strong thin-film ferromagnetic metal are arranged in a

grid, where vertical elements (R1, R3) and horizontal elements (R2, R4) are serially

connected, forming a full bridge.

The MR sensor has the basic equivalent circuit shown in the drawing:

22

Figure 4

Figure 5

MR sensor device

This is a small magnetoresistive sensor with high sensitivity, demonstrating excellent

performance in noncontact position detection. This sensor is used in products such as

mobile phones.

Mobile phones, notebook personal computers, electronic dictionaries, gas

meters,cylinders, water heaters, FA devices, etc.

Detection of opening and closing covers or doors: Mobile phone, notebook personal

computers, microwave ovens, washing machines, rice cookers, refrigerators, etc.

Detection of positions: Air cylinders, antitheft windows, etc.

Measurement of water levels (detection of magnet floats):

Toilets with washing functions, electronic jars, humidifiers, etc.

Power supply switch: Cordless telephones, electric toothbrushes, etc. MR sensor device

This is a small magnetoresistive sensor with high sensitivity, demonstrating excellent

While both magnetoresistive and integrated Hall sensors measure the strength of magnetic

field components, they do so in different ways and this can directly affect their successful

use in a position sensing application. Choosing which of the two is a better fit for your

application may require you to consider sensor characteristics that don't show up on

manufacturers' data sheets. This article is designed to help your decision process by

reviewing two angle sensors—an anisotropic magnetoresistive (AMR) sensor and a Hall

sensor—in a position-sensing application example.

23

After I understand what is MR sensor and how it works then I perform a MR sensor

checking between high sensitivity and low sensitivity. I have also hand over a report to my

supervisor regarding on this checking.

Figure 6

1) Then, plug in the DC cable

24

2) In order to obtain best result, make sure each time when to perform the checking, the

camcorder is RESET. If the camcorder in standby mode, it will not give an accurate

result.

3) There are 4 type of angle need to be taken which are opening, closing, rotating

clockwise, and rotating anti-clockwise position.

4) To obtain opening angle, angle in opening position should be noted

*firstly place the camcorder on the flexible protractor

25

Figure 7

Figure 8

Slightly move the LCD panel towards to the left. The moment opening interface appears

angle is noted as opening angle.

26

Figure 9

Figure 10

5) The closing angle starts when the LCD panel is 90 degree towards the body of

camcorder.

* then slowly move the LCD panel toward to right which is the closing position of

camcorder.The moment the camcorder turns off, angle from the body is noted as closing

angle.

27

Figure 11

28

Figure 12

Figure 13

6) Next, angle of rotating anti-clockwise need to note.

Make sure the LCD panel 90 degree towards the body of camcorder

* Start rotating the LCD panels anti-clockwise until the interface changes to opposite view.

29

Figure 14

Figure 15

* Take a flexible protractor measure the angle has been shown in diagram.

7) Next, angle of rotating clockwise need to be noted

* Make sure the LCD panel is 90 degree towards the body and the LCD panel facing the

opposite view.

30

Figure 16

Figure 17

*Start rotating the LCD panel clockwise till interface change. * Angle is noted with the

flexible protractor.

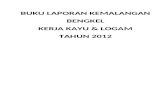

8) Results were noted in a table format. Such as

no open close Hon Hoff

1 26 15 130 125

2 23 17 131 110

3 22 15 125 115

4 27 13 130 120

5 24 20 130 110

6 25 20 130 110

7 26 20 130 115

8 24 20 130 120

31

Figure 18

9 25 20 130 115

10 24 20 130 110

MR Sensor Report Review by Sopna

PURPOSETo perform checking of the effective of the MR Sensor

HYPOTHESIS

If it takes a small angle to detect the magnet hence it is a low sensitivity MR Sensor while

If it takes a large angle to sense hence it is a high sensitivity MR Sensor.

METHOD1) Before performing the experiment, it was wise to place a paper below the product to

ground it. Also, performed checking of cables and unassembled the components and

then assemble it, before each testing in order to avoid error in measurement.

2) Measurement of angle is taken while in open position, close position, rotating

clockwise and rotating anti-clockwise the LCD panel.

3) Two types MR Sensor were manipulated during experiment which are high sensitivity

MR sensor and low sensitivity MR sensor.

4) Each MR Sensor was tested for 10 times.

32

RESULTS

REFERENCE

DATA

shutting detection : 25°

opening detection : 29.6°

rotation detection (Hon) :

128.1°

rotation detection (Hoff) :

120.4°

Low sensitivity

no open close Hon Hoff

1 28 20 125 120

2 27 23 130 125

3 27 21 125 120

4 25 20 125 120

5 27 20 125 123

6 29 20 125 120

7 29 20 125 120

8 27 18 125 120

9 27 15 125 120

10 29 19 125 120

Average 27.5 19.6 125.5 120.8

33

Margin -2.1 -5.4 -2.6 0.4

High sensitivity

no open close Hon Hoff

1 26 15 130 125

2 23 17 131 110

3 22 15 125 115

4 27 13 130 120

5 24 20 130 110

6 25 20 130 110

7 26 20 130 115

8 24 20 130 120

9 25 20 130 115

10 24 20 130 110

Average 24.6 18 129.6 115

Margin -5 -7 1.5 -5.4

CONCLUSION

34

1) As being shown in the table above, the results differ from the hypothesis. Margin for

High sensitivity is higher compared to the low sensitivity. Supposingly margin for low

sensitivity should be higher.

2) Results above shows that low sensitivity is a better option since its margin is quite

closer towards the reference data.

3.3 Checking linearity in Touch Panel

A touchscreen is an electronic visual display that can detect the presence and location of a

touch within the display area. The term generally refers to touching the display of the

device with a finger or hand. Touchscreens can also sense other passive objects, such as a

stylus. Touchscreens are common in devices such as game consoles, all-in-one computers,

tablet computers, and smartphones.

The touchscreen has two main attributes. First, it enables one to interact directly with what

is displayed, rather than indirectly with a pointer controlled by a mouse or touchpad.

Secondly, it lets one do so without requiring any intermediate device that would need to be

held in the hand (other than a stylus, which is optional for most modern touchscreens).

Such displays can be attached to computers, or to networks as terminals. They also play a

prominent role in the design of digital appliances such as the personal digital assistant

(PDA), satellite navigation devices, mobile phones, and video games.

The popularity of smartphones, tablet computers and many types of information appliances

is driving the demand and acceptance of common touchscreens for portable and functional

electronics. With a display of a simple smooth surface, and direct interaction without any 35

hardware (keyboard or mouse) between the user and content, fewer accessories are

required. Touchscreens are popular in the medical field, and in heavy industry, as well as

kiosks such as museum displays or room automation, where keyboard and mouse systems

do not allow a suitably intuitive, rapid, or accurate interaction by the user with the display's

content.

Historically, the touchscreen sensor and its accompanying controller-based firmware have

been made available by a wide array of after-market system integrators, and not by display,

chip, or motherboard manufacturers. Display manufacturers and chip manufacturers

worldwide have acknowledged the trend toward acceptance of touchscreens as a highly

desirable user interface component and have begun to integrate touchscreens into the

fundamental design of their products.

A resistive touchscreen panel comprises several layers, the most important of which are two

thin, transparent electrically-resistive layers separated by a thin space. These layers face

each other, with a thin gap between.The top screen (the screen that is touched) has a coating

on the underside surface of the screen. Just beneath it is a similar resistive layer on top of

its substrate. One layer has conductive connections along its sides, the other along top and

bottom. A voltage is passed through one layer, and sensed at the other. When an object,

such as a fingertip or stylus tip, presses down on the outer surface, the two layers touch to

become connected at that point: The panel then behaves as a pair of voltage dividers, one

axis at a time. By rapidly switching between each layer, the position of a pressure on the

screen can be read.

Resistive touch is used in restaurants, factories and hospitals due to its high resistance to

liquids and contaminants. A major benefit of resistive touch technology is its low cost.

36

Disadvantages include the need to press down, and a risk of damage by sharp objects.

Resistive touchscreens also suffer from poorer contrast, due to having additional reflections

from the extra layer of material placed over the screen

A capacitive touchscreen panel consists of an insulator such as glass, coated with a

transparent conductor such as indium tin oxide (ITO).As the human body is also an

electrical conductor, touching the surface of the screen results in a distortion of the screen's

electrostatic field, measurable as a change in ent to the controller for processing. Unlike a

resistive touchscreen, one cannot use a capacitive touchscreen through most types of

electrically insulating material, such as gloves; one requires a special capacitive stylus, or a

special-application glove with an embroidered patch of conductive thread passing through

it and contacting the user's fingertip. This disadvantage especially affects usability in

consumer electronics, such as touch tablet PCs and capacitive smartphones in cold weather.

In response, there are gloves on the market with one or more fingertips that include

conductive material, thus overcoming this limitation. The largest capacitive display

manufacturers continue to develop thinner and more accurate touchscreens, with LCD

touchscreens for mobile devices now being produced with 'in-cell' technology that

eliminates a layer, by building the capacitors inside the LCD itself. This type of

touchscreen reduces the visible distance (within millimeters) between the user's finger and

what the user is touching on the screen, creating a more direct contact with the content

displayed and enabling taps and gestures to be even more responsive.

Methods of checking linearity

37

1) Checking linearity of the touch panel is an important process to know wheater the panel

will be responding to the stylus (finger).

2) In touch panel, the conductive electrodes from orthogonal electric fields in the X and Y

direction across the resistive layer. Contact of a finger or stylus on the panel then causes

the generation of a signal that is representative of the X and Y coordinates of the

location of the finger with respect to the substrate. In this way, the associated touch

panel circuitry can ascertain where the touch occurred on the substrate

3) Firstly assemble the touch panel and the main pwb .

38

Figure 19

4) From main pwb make a jumper for 4 nodes, which is X+, X-,Y+ andY-..If you are

doing X linearity, hence you must connect the jumper Y+ to ground, X- to output, Y- to

power supply which is 2.8V.

5) It is wise that to make a grid and place it below the touch panel layer. Please make sure

the grid are even and equal and coordinate them with numbers such as a , b, c, etc for

horizontal line while vertical line 1,2,3 and etc.

6) Then make a jumper for the nodes, Y+, Y-, X+ and X-. Since you choose to do X

linearity Y+ connected to ground, Y- connected to power supply and X- connected to

Digital Multimeter.

39

Figure 20

Figure 21

7) Input is connected to power supply. Output is connected to power supply

Figure 22

40

8) Place a stylus on 1 box that you have drawn, note down the reading from Digital

Multimeter. That is known as voltage for each box.

41

Figure 23

Figure 24

9) In order to get Emax. By using the stylus, make linear line from 1 point to another

point. Such as,Va1 to Vr1 line has to be made by using stylus.

Figure 26

10) To obtain Linearity, L calculation had to be had done base on the formula below.

42Linearity, L =

∆ EmaxX 100%

Va1 - Vr1

Figure 25

11) Graph is plotted based on results such as,

Figure 27

3.4 Checking overall resistance for touch panel

43

A touch panel or touchscreen is a touch-sensitive transparent screen mounted in front of an

LCD. It provides a way for a person to interact with an computer system. Typically the

system will display buttons on the LCD and expect the user to select one by touching it.

The touch causes some measurable phenomena which is converted by a controller IC into

screen coordinates which are sent into the system. The system then determines which

button was pressed and takes appropriate action. The phrases Touchscreen, Touch Panel

and Touch Screen mean the same thing and are interchangeable.

A resistive touch screen works by applying a voltage across a resistor network and

measuring the change in resistance at a given point on the matrix where a screen is touched

by an input stylus, pen, or finger. The change in the resistance ratio marks the location on

the touch screen. Hence, when producing an electronic product that uses touch panel, we

must make that is resistance within range, if not it will bring damage to the product. To

operate a 4 wire resistive touch panel, the system must keep a voltage gradient on the panel

while waiting for a sense voltage to indicate a touch. The sense voltage gives one

coordinate and then the voltages are immediately applied to the other direction and sensed

again to obtain the other coordinate. The need to be on all the time while awaiting a touch

essentially requires that a controller IC be used.

1) Testing should be executed at room temperature.

44

Figure 28

2) Disassemble the touch panel set. Identify that the Y terminal is 1 and 3, while X

terminal is 2 and 4.

3) Tap probe of multimeter at the Y terminal (Line 1 and Line 3). Reading was noted.

Figure 29

45

4) Tap probe of multimeter at the X terminal (Line 2 and Line 4)

Figure 30

5) Since resistance is measured, the unit obtained should be in ohm.

Figure 3146

6) Results was tabulated in table such as,

Resistance Between

Terminals

x Direction 120 ~ 390 Ω

y Direction 300 ~ 1100 Ω

CHAPTER 4: Conclusions and Suggestions

4.1 Conclusion

I have manage to find opportunity for me to gain access to information on the current

needs and requirements of industry and also exposed myself to the latest technology

and management utilized by industry.

47

I have enable to gain experience and exposure to the reality of working environment

in organizations and also provide opportunity for me to be involved as workers in

organizations.

I have develop myself with necessary technical and professional skills including

communication, management and entrepreneurship.

I have also understand how R&D department works which is research and

development (R&D) department is responsible for innovations in design, products, and

style. This department is responsible for creating innovative new products to keep JVC

a step ahead of the competition. Many companies also rely on the research and

development department, or R&D Department, to improve existing consumer

products, and to explore new ways of producing them.

4.2 Suggestions for Final Year Project

I have planned to create a camcorder to be operated in Zigbee wifi since the latest

camcorder focusing on monitoring which connects through indirect monitoring which

is through router.

ZigBee is a low-cost, low-power, wireless mesh network standard. The low cost allows

the technology to be widely deployed in wireless control and monitoring applications.

Low power-usage allows longer life with smaller batteries. Mesh networking provides

high reliability and more extensive range. ZigBee chip vendors typically sell integrated

radios and microcontrollers with between 60 KB and 256 KB flash memory.

48

ZigBee operates in the industrial, scientific and medical (ISM) radio bands; 868 MHz in

Europe, 915 MHz in the USA and Australia, and 2.4 GHz in most jurisdictions

worldwide. Data transmission rates vary from 20 to 900 kilobits/second.

The ZigBee network layer natively supports both star and tree typical networks, and

generic mesh networks. Every network must have one coordinator device, tasked with

its creation, the control of its parameters and basic maintenance. Within star networks,

the coordinator must be the central node. Both trees and meshes allows the use of

ZigBee routers to extend communication at the network level.

ZigBee protocol stack

ZigBee builds upon the physical layer and medium access control defined in IEEE

standard 802.15.4 (2003 version) for low-rate WPANs. The specification goes on to

complete the standard by adding four main components: network layer, application

layer, ZigBee device objects (ZDOs) and manufacturer-defined application objects

which allow for customization and favor total integration.

Besides adding two high-level network layers to the underlying structure, the most

significant improvement is the introduction of ZDOs. These are responsible for a

number of tasks, which include keeping of device roles, management of requests to join

a network, device discovery and security.

49

ZigBee is not intended to support powerline networking but to interface with it at least

for smart metering and smart appliance purposes.

Because ZigBee nodes can go from sleep to active mode in 30 ms or less, the latency

can be low and devices can be responsive, particularly compared to Bluetooth wake-up

delays, which are typically around three seconds

50