Zeleznicke Dilatacije

-

Upload

aerodanger -

Category

Documents

-

view

223 -

download

0

Transcript of Zeleznicke Dilatacije

-

8/13/2019 Zeleznicke Dilatacije

1/5

Dilatacione spojniceza eleznicu imaju

sledee funkcije:

dozvoljavaju pomeranja izmeu

ploa,omog uava ju dren au i

filtraciju atmosferskih voda,

daju kontinuitet konstrukcije ploa,

spreavajui prodiranje tucanikog

zastora u dilatacioni zazor,spreavaju prolazak lutajue

struje.

Dilatacije Algaflex TW za eleznice u

seizmikim podrujima su odobrene od

strane Ferrovie dello Stato i odgovaraju

propisanim uslovima.

ALGAFLEX dilatacije su napravljeneod elektrino neprovodljivih gumen ih

elemenata, vulkanizovanih preko unu-

tranje metalne konstrukcije.

Ova konstrukcij a, koja se ponaa

kao anker i armatura, je potpuno presvu-ena gumom.

ALGAFLEX TW elementi su privr-

eni za plou hemijskim ankernim

zavrtnjima, dozvoljavajui deforma-

ciono pomeranje gumenih slojeva,

ukljuujui i izmeu metalne konstrukcije.

Dilatacije se vezuju nastavkom pero-ljebi zaptivene specijalnim lepkom.

Nepropusno neoprensko platno je oblika

grkog znaka omega i montira se popreno

u odnosu na konstrukciju.

Dilatacija za koju se daje garancija od

10 godina, otporna je na ulja, masti, gorivo,

so i pesak. Toplota, izloenost suncu,hladnoa i sneg ne prouzrokuju prevre-

meno starije.

Pokrivne ploe za peake staze dozvo-

ljavaju pomeranje du razliitih

delova konstrukcije, spreavaju da

tucaniki zastor ili strana tela prodru u

zazor i garantuje elektrinu izolaciju.

Stoga je mogu e savit i pokriv nepl o e pr ek o ivi n ja ka p e a ki h

staza.

Kad je kosi ugao vei od , pokrivna10

ploa moe da zameni savijeni deo

kraja dilatacije.

Opis

Pokrivna ploa

The railways expansion joints have the

following functions:they allow the movements between the

decks,

they permit the drainage and preventthe percolation of the meteoric waters,they give a structural continuity to the

slabs, avoiding the penetration of the

ballast in thegap,They prevent the forward of stray

electrical currents.The TW Algaflex joint for railways inseismic areas, has been ratified by"Ferrovie dello Stato" and complies withthe specifications.

The Algaflex joints are made of dielectric rubber elements, vulcanised

to the innermetallic structure.This structure, which acts as anchor and

reinforcement, is completely covered by

the rubber.The Algaflex TWelements are restrained

to the slabs by chemical anchor bolts,

allowing the deformation movement of

the rubber layers included between the

metallic structures.The joints are connected by male-

fem ale jun ctions and sealed wit h

special glue.

The dielectric flashing is shaped

andis put across allthe structure.The joint, guaranteed for 10 years, is

resistant to oils, grease, petrol, salts

andsand.Hea t, exp osu re to the s un, col d, sno w

d o n o t c a u s e e a r l y a g e i n g

phe nom ena .

The cover plate for the sidewalks

allows the movements among the

different parts of the structure; it

avoids to ballast or foreign bodies to

enter the gap and guarantees the

electricisolation.It is pos sib le, therefo re, to ben d the

cover plate against the kerbs of the

sid ewa lks .

When the skew angle is higher than10 the cover plates can replace the

bendedpartontheendofthejoint.

Description

Coverplate

TW

APPROVED

ODOBRENE

-

8/13/2019 Zeleznicke Dilatacije

2/5

TYPICAL STRAIN-DEFLECTION PLOT

TIPINO OPTEREENJE - DIJAGRAM DEFLEKCIJE

Sfo

rz

-S

o

train

[kN/m]

Deflekcija - Deflection [mm]

0

6

12

15 30 45 60

18

24

B

A

A)Spore deformacije:Termike varijacije,kontrakcije, puenje BB)Brze deformacije: na osnovukoenja i seizmikih delovanja

A) Slow deformation:thermic variations, shrinkage,concrete fluage;B) Quick deformations due tobraking and seismic events

ALGAFLEX TW 130

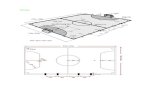

POPRENI PRESEK - CROSS SECTION

NASTAVAK PERO-LJEBM/F JUNCTION

OSNOVA - PLAN

F M

M F

IZNAD ABOVE ISPOD- BELOW

294

220

125

2000

7x250 125

05 2

20

294

05

-

8/13/2019 Zeleznicke Dilatacije

3/5

pero-ljeb nastavak spojen elastinim lepkom

m/f junctions sealed with elastic sealantmf

360

0

100

15

var. var.

Ballast

Br. punih jedinica= N. full units =

mf mf mfmfpokrivna ploacover plate

POKRIVNA PLOA - COVER PLATE

TIPINA MONTAA - TYPICAL INSTALLATION

Apsorpcija vertikalnih pomeranja - Vertical movements assorption

-

8/13/2019 Zeleznicke Dilatacije

4/5

Pos.

Opis

TipD

escription

Type

Materijal

irina

Material W

idth

Standrad

Standard

Zazor

GapG

W

Algaflex-Guma

-Rubber

Algaflex-Armatura

-Reinforcing

Hemijskianker

Chemicalanchorage

Navrtka/Rondelle

Podloka/Washers

LimStainlesssteelsheet

Centrirajuiprsten

Centeringring

Malterzaovalnerupe

Ovalholesfilling

Drenanacev

Drainpipe

Dielektrinoplatno

Dielectricalflashing

Dijalektinaprirodnagum

a

-Dielectricalnaturalrubb

er

elikS275JR

Steel

elikC40+DACROME

T320

Steelandprotection

Cl.6S/R40+DACROM

ET320

Classandprotection

X5CrNi18/10

Polipropilen-Polypropylene

Neskupljajuireoplastin

imalterTIGIGROUT102FR

Nonshrinkrheoplasticfiber-reinforcedmortar

Plastinadrenanacevpokrivenageotekstilom

PVCstiffwithholescove

redbynotwovenfabric

Hypalon

CNR10018

7050

EN10025

55550

10075

EN10083

68575

120100

805100

UNI5588/6592

180160

1105160

EN

10088

1a

1b 2 3 4 5 6 7 PE

Epoksizaprelaznetrake

Blackepoxytransitionstrip

Postojeavodonepropusnost

Existingwaterproofing

0 16

010

50

85

20

220

294

490

100

E

3

4

85

71a

P

1b

2

6

8

LEGENDA

DIMENZIJE-DIMENSIONS[mm]

POPRENIPRESEK-

CROSS

SECTIONS

AL

GAFLEXTW130

AL

GAFLEXTW50/100-TW7

5/150-TW100/200-TW10

0/320

TW100/320

TW100/200

TW75/150

TW50/100

G

W

100

230

100

50

392

392

-

8/13/2019 Zeleznicke Dilatacije

5/5

GARANCIJA KVALITETA - QUALITYASSURANCE

REALIZZAZIONEUFFICIO

C

T

IT

TECNIOALGA-SAMPAPR

ESSPON

APPARECCHI DAPPOG IO E GIUNTI DI DILATAZIONE - DISPOSITIVI ANTISISMICIG

ALGA SPA - VIA LONA 12 - 20123 MILANO - TEL. +39 02 48569.1 - FAX + 9 02 48569.245 - HTTP://WWW.ALGA.ITO 3

POSTTENSIONE- STRALLI E TECNOLOGIE SPECIALIPER LECOSTRUZIONIBRIDGE BEARINGS AND EXPANSION JOINTS - ANTISEISMIC DEVICES - POST-TENSION - STAY CABLES - ADVANCED TECHNOLOGIES FOR CONSTRUCTION

Ureaj za testiranje sa hidraulikimpresama napravljen je u naoj labora-toriji za ispitivanje kvaliteta, a ucilju ispitivanja Algaflex dilatacija.

podizanje ploe.

dilatacije sa i bez optereenja dopredviene vrednosti do minimalnogi maksimalnog pomeranja.

pomeranja.Fiziko-mehanikidielektrikitestovi

S. ulijanu kod Milana.

u Seriateu kod Bergama.Svi testovi se izvode u prisustvu FSinspektora.

Podizanje kako bi se simuliralo

Ciklini test otvaranja i zatvaranja

Hidraulini test se izvodi po testu

izvode se u institutu -CERISIE u

Dinamiki testovi su izvoeni u ISMES

Alga projektuje i proizvodi u skladu sa

UNI EN ISO 9001.94 izdatim od strane

IGQ.Alga plans and produces with Quality

System, complying with UNI EN ISO

A test tank, working with hydraulic

9001.94 certified from IGQ.

jacks, has been built in our QualityLaboratory in order to test the AlgaflexTW joints.

In this test tank, some test have beenexecuted:

to simulate thedeck liftingof opening and closing of

the joint, with and without overload,up to the min and max movement

foreseen.

carried out after themovement tests.

T h e a n d have been carried out at

Istituto CERISIE in S. Giuliano, (MI).The have been carried outat ISMES in Seriate, (BG).

All the tests have been carried out in thepresence of FS inspectors.

LiftingCyclic tests

Hydraulic tests

p h y s i c a l - m e c h a n i c a ldielectric tests

dynamical tests

Slika levo: Test podizanja ploe domaksimalne dozvoljene vrednosti, zazamenu leita.

Slika desno: Oleodinamika oprema zatestiranje rezervoara, gde su nekatestiranja izvedena na zahtev Ferroviedello Stato.

On theleft: Deck lifting test, to themaximumallowed value, for the bearings replacement.

On the right: The oleodynamic equipment tooperate the test tank, where some tests havebeen carried out following the FerroviedelloStato requests.

Polimer -Polymer: CNR 10018-87Dielektrina guma -Dielectric rubber

UNI 491660 5 Shore A

UNI 606521 N/mm

2.5 M

UNI 6065490 %

EN10025S275 JR

vrstoa -Hardness

Zatezna vrstoa - Tensile strength

Izduenje kod prekida - Ultim. elongation

Elekrina otpornost - Electrical resistance

Armaturni elik - Reinforcing steel

FIZIKE OSOBINE -PHISICAL PROPERTIES

Na ovom ureaju obavljena su testiranja: